-

Recovery of Lignosulfonates from

Spent Sulphite Liquor

Separation and purification of Lignosulfonates,

present in spent sulphite liquor, has been carried

out through a Dia-filtration operation. Around

80-85% recovery is obtained. The technology

development is complete and ready for pilot plant

trial. Results of molecular mass distribution of

lignosulphates have shown that variable size

distribution may be obtained by using different

cut-off size of membranes.

* P. K. Bhattacharya, R. K. Todi, M. Tiwari, C.

Bhattacharjee, S. Bhattacharjee, S. Dutta, “Studies

on UF of spent sulphite liquor (SSL) using various

membranes for the recovery of lignosulphonates“,

Desalination, 174, 287 – 297 (2005).

-

Micellar Enhanced Ultrafiltration (MEUF)

In MEUF process, the surfactant having charge

opposite to target ions, is added to the effluent

stream containing the metal ions at a concentration

greater than the critical micellar concentration

(CMC), so that they form aggregates of around 50–150

of monomer molecules, called micelles. Therefore, a

large fraction of the metal ions get

electrostatically attached to the micelle surface.

Retention of such metal ions attached to the

micelles is possible if the resulting solution is

passed through an ultrafilter, having pore size

smaller than the micelle diameter. The recovery and

the reuse of surfactant are of utmost importance

from economical point of view. Several studies were

done for the removal of metal ion and organic

solutes under aqueous medium through MEUF under both

stirred and unstirred conditions using batch cells.

Bonding or solubilizations of these solutes in

surfactant micelles were also experimentally

ascertained. Mathematical models were also

developed.

* M. Syamal, S. De and P. K. Bhattacharya, “Phenol

solubilization by cetyl pyridinium chloride micelles

in micellar enhanced ultrafiltration“, J.

Membrane Sci., 137, 99-107 (1997).

* S. Ralph Jadhav, N. Verma, A. Sharma and P. K.

Bhattacharya, “Flux and retention analysis during

micellar enhanced ultrafiltration for the removal of

phenol and aniline“, Separ. Purif. Technol., 24,

541-557 (2001).

* Gargi Ghosh and Prashant K. Bhattacharya, "Hexavalent

chromium ion removal through micellar enhanced

ultrafiltration", Chem. Eng. J.: Environ. Chem.

Eng., 119, 45 - 53 (2006).

-

Hydrazine Hydrate Separation through

Pervaporation

Hydrazine is an important inorganic chemical that

upon combustion produces nitrogen and water, unlike

hydrocarbon fuels producing carbon dioxide and

water. Hydrazine is less flammable and less volatile

than hydrocarbon fuels and hence it is used as a

component in jet fuels because it produces a large

amount of heat when burned. It finds active

applications in rocket propulsion; however, in

anhydrous hydrazine form. By ordinary distillation,

64 wt.% of hydrazine is produced. Therefore, removal

of water from hydrate state to produce anhydrous

hydrazine is essential. Conventional separation

technique, like distillation forms an azeotrope with

water at 71.5 wt% of hydrazine. Further, hydrazine

and water, being highly polar substances (surface

tension values very close) impart strong hydrogen

bonding between them. Therefore, pervaporation

processes* is recommended to seek dehydration.

* S. V. Satyanarayana, P. K. Bhattacharya,

“Pervaporation of Hydrazine Hydrate: Separation

characteristics of membranes with hydrophilic to

hydrophobic behaviour“, J. Membrane Sci., 238,

103 -115 (2004).

* Nazish Hoda, Satyanarayana V. Suggala and Prashant

K. Bhattacharya, “Pervaporation of Hydrazine – Water

through Hollow Fiber Module: Modeling and

Simulation“, Computers Chem. Eng., 30 (2),

202-214 (2005).

* Mrinal Kanti Mandal, Sukalyan Dutta and P. K.

Bhattacharya, “Characterization of Blended Polymeric

Membranes for Pervaporation of Hydrazine Hydrate”,

Chem. Eng. J., 138, 10-19 (2008).

-

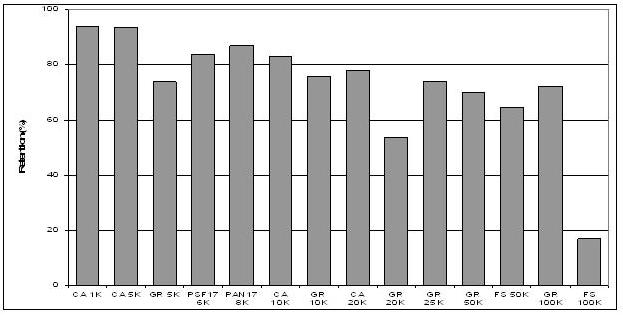

Ultrafiltration of Sugar Cane Juice

for recovery of Sugar

Sugar industry is one of the largest agro-based

industries in India; however, suffer from many

problems. There is need to investigate the energy

saving and technically efficient alternative

processes. Application of the integrated membrane

technology is has been attempted (processes like RO,

UF, MF and ED. Such processes may offer certain

advantages in clarification and concentration of

multi-component solutions and suspensions like sugar

cane juice. However, the membrane systems pose

problems like decline of flux over time which

prevents widespread applicability of such processes

commercially. Several studies* were made

accordingly.

* A. D. Sarode, N. Verma and P. K. Bhattacharya,

“Analysis of retention and flux decline during

ultrafiltration of limed sugarcane (clarified)

juice“, Chem. Eng. Commun., 188, 179-206

(2001).

* U. V. S. RamGopal, N. Verma and P. K.

Bhattacharya, “Analysis of flux decline during

ultrafiltration of sugarcane juice (limed) using

cross-flow cell“, Can. J. Chem. Eng., 80(1),

105-115 (2002).

* P. K. Bhattacharya, Shilpi Agarwal, S. De and

U.V.S. RamaGopal, “Ultrafiltration of sugar cane

juice for recovery of sugar: analysis of flux and

retention“, Separ. Purif. Technol., 21,

247-259 (2001).

-

Enzymatic (immobilized) Membrane

reactor

Enzymatic hydrolysis of lactose mainly yields

glucose and galactose. In addition galacto-oligosaccharides

(GOS) are also formed by transgalactosylation

activity of enzyme from the same biochemical

reaction. GOS is a very beneficial functional

component for human. GOS, also recognized as

prebiotics consists of a number of oligosaccharides

which are linked with different b-glycosidic bonds,

depending on enzyme source. Work is going on in this

direction.

-

Prehydrolysis Liquor Treatment to

Disposal Level

Treatment of prehydrolysis liquor was done

biologically using sacchromyces cerevisiae,

zymomonus mobilis and torulla utilis as strains,

which convert sugar into yeast. High percentages (75

to 90%) of reductions in sugars, COD, BOD and total

dissolved solids were observed. Modeling was done to

predict the rate equations for all the cases.

Further to this biological treatment,

ultra-centrifuging was done to separate out the

formed yeast. The clarified biologically treated

liquor was then subjected to UF/ RO to obtain the

desired level of quality of permeate for disposal.

The membrane operation becomes extremely simpler

because of the depletion of micro-solutes (by bio

means) as the osmotic pressure of the feed solution

gets drastically reduced.

* R. L. Rath, C. Bhattacharjee, Shikha Jain, P. K.

Bhattacharya, “Treatment of prehydrolysis liquor

from pulp mill using biological route followed by

Reverse Osmosis“, Chem. Eng. Technol., 28 (10),

1201-1211 (2005).

* R. Jayan, C. Bhattacharjee and P. K. Bhattacharya,

“A combined biological and membrane based treatment

of prehydrolysis liquor from pulp mill“, Separ.

Purif. Technol., 45 (2), 119-130 (2005).