CHAPTER 1

WHY LASERS

1.1 Total Quality Control

The growth of an unprecedented new kind of world market-place of volume and variation coupled with the rising expectations of buyers, the changing role of government and the debates about the pollution, has intensified the demands on business management in general and on total quality control in particular. The customer demand for greater durability and reliability in products/services has increased explosively in our daily lives and schedules depend totally upon the satisfactory performance and operation of products/services; could be a washing machine for growing young family, an instrument in a hospital ward, an electrical or a telephone network or an automobile used almost 14 hours a day by a family. Though buyers continue to purchase with a strong attention to price, yet they place higher emphasis on quality. First time buyers are attracted by price as well as by quality and it is quality alone which brings buyers back for the 2nd, 3rd and nth time, making quality control a fundamental determinant for business health, growth and economic viability.

Quality is based upon the customer's actual experience with the product or service, measured against his/her requirements-stated or unstated, conscious or merely sensed, technically operational or entirely subjective - making the quality a customer determination. Reliability, serviceability, maintainability and attractability are the characteristics which make up the composite of product/service quality and economic balancing-off these individual characteristics establishes the 'quality' of a product/service. The word 'quality' does not have to be popular meaning of a 'best' in any abstract sense. To industry it means 'best' for satisfying certain customer conditions, the important being (1) the actual end use and (2) selling price. The two conditions are reflected in 10 additional product service conditions:

1. The specification of dimensions and operating characteristics.

2. The life and reliability objectives.

3. The safety requirements.

4. The relevant standards.

5. The engineering, manufacturing and quality costs.

6. The production conditions under which the article is manufactured.

7. The field installation, maintenance and service objectives.

8. The energy utilization and material conservation factors.

9. The environmental and other "side" effects consideration.

10. The costs of customer operation.

In view of these conditions quality control activities must exist in all the main-line operations: marketing, design engineering, production, industrial relations, services and similar key areas. The modern total quality view sees the prototype quality control person not as an `inspector' but a quality engineer and manager with an adequate background in the relevant product technology, system engineering and system management as well as training in statistical method, human behavior and motivational approaches, inspection and testing techniques, reliability studies, safety practices and other such tools for improving and controlling quality. The theme of the new approach is not "bad parts shall not pass" but "make them right the first time". Emphasis is on "defect prevention' so that routine inspection will not be needed to as large as extent. The burden of ensuring quality of a product/service does not rest with inspector but with contributors to the quality of the parts and products: design engineers, sales planners, managers, machinists, assembly, foremen, vendors, product service engineers, as the case may be. Total quality control focuses on examining the processes in an operation, to learn where the mistakes are made, why these mistakes are happening and if it is possible, practical and economically desirable to prevent them from recurring. Inspection has its place in total quality control, but it is inspection of a process and not the inspection of the product as is the case with traditional quality control. To ensure total quality control an industrial cycle is divided in the following eight stages:

1. Marketing: To evaluate the level of quality which customers want and for which they are willing to pay.

2. Engineering: To reduce the marketing evaluation to exact specifications.

3. Purchasing: To choose, contract with and retain vendors for parts and materials.

4. Manufacturing Engineering: To select jigs, tools and processes for production.

5. Manufacturing Supervision and Shop Operations: To exert a major influence during parts making, subassembly and final assembly.

6. Mechanical Inspection and functional Test: To check conformance to specifications.

7. Shipping: To influence caliber of packing and presentation

8. Installation and Service: To help proper operation by installing the product according to proper instructions and maintaining it through service.

The methods used to measure and analyze a process to ensure quality control have to be reliable, quick and cost effective. For quickness and cost-effectiveness, the method used to analyze a process should be ‘on-line’. That is the specifications of the products are checked while the process is going on and corrective measured can be initiated in case desired results are not obtained . The method has to be ‘non-interfering’ and should be such so that corrective measures can be initiated automatically in case of problems in the process. For example, if a chemical reaction is the process, one should be able to monitor the reaction so as to ensure the desired products and if desired results are obtained, corrective measures should be initiated so as to create reaction conditions (temperature, pressure and concentration etc) to get the desired products. Monitoring method should not interfere with the reaction.

Lasers which emit coherent electromagnetic radiation in infrared, visible and UV regions are remarkable devices finding applications in 'on-line' measurement and analysis of processes for total quality control; could be the analysis of a chemical reaction or monitoring of dimensions/ flaws/ finish of an end product or part of a product. All this analysis can be 'non-interfering' and also by proper feed back-loops corrective measures can be initiated automatically-making it both ecnomic as well as less time consuming. The basic properties of laser radiation which make lasers 'super tools' are:

1.2 Radiance

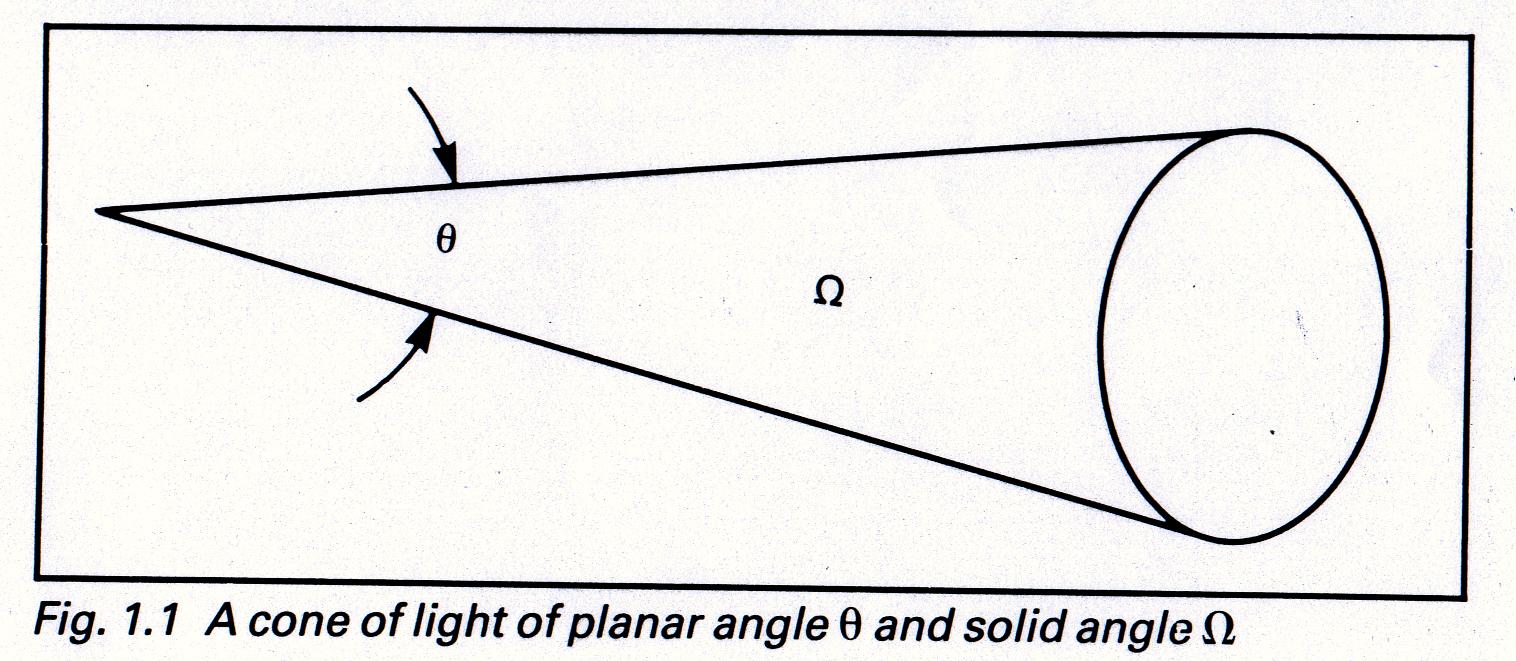

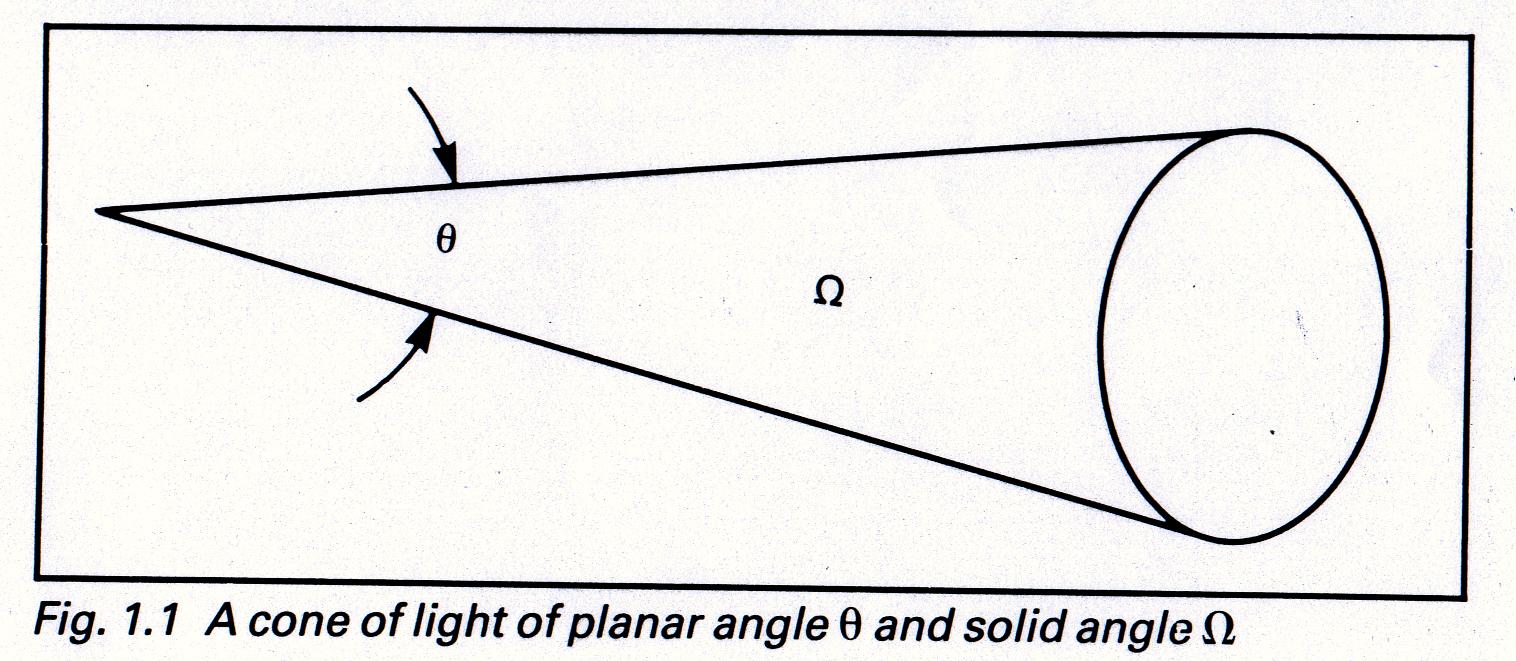

The radiance of a source of light is power emitted per unit area of the source per unit solid angle. The units are watts per square meter per steradian. A steradian is the unit of solid angle which is three-dimensional analogue of conventional two-dimensional (planar) angle expressed in radians. Hence, the solid angle unit is called a steradian (stereo-radian) as in three-dimensional or whole angle. For small angles the relation between a planar angle and the solid angle of a cone with that planar angle is to a good approximation is:

W = ( p / 4) q 2

where q is the planar angle and W is the solid angle. This is illustrated in Fig. 1.1.

Lasers generally have an extremely high radiance output. For example, a helium-neon (He-Ne) laser with an output of 1mW will have an output spot diameter of about 1mm and a beam divergence (angle of the cone into which the light is spreading) of about 1mrad. Thus, the solid angle:

W = ( p /4 )( 1 mrad)2 = 0.8 ´ 10 – 6 sterad

and the radiance R = [ 1 mW/p ( 0.5mm)2 0.8 ´ 10 – 6 sterad ] = 160 ´ 10 6 W / m 2 sterad

while for sun R = 1.3 ´ 10 6 W / m2 sterad even though it emits a power of 4 ´ 10 26 W.

The high radiance of lasers results in small spot sizes when mirrors or lenses are used to focus the beam, producing very high irradiance.

1.3 MonochromaticityThe term monochromaticity literally means single colour or single wavelength. However, no light source (or any electromagnetic source for that matter) is perfectly monochromatic. Lasers tend to be relatively more monochromatic. However this depends on the type of laser, and special techniques can be used to improve monochromaticity to one part in a million for standard commercial systems for interferometric measurement applications or much better in scientific lasers for seismographic work or frequency standardization.

Lack of perfect monochromaticity is quantitatively expressed in terms of wavelength bandwidth or frequency bandwidth. Fig. 1.2 illustrates the dependence of power on wavelength. The frequency bandwidth for a typical He-Ne laser is about 1500MHz (full width at half-maximum, FWHM). At a wavelength of 632.5nm this means a wavelength bandwidth of about 0.2nm. The bandwidth of a diode laser with a wavelength of 900nm is about 10nm compared with an LED which has a bandwidth of approximately 300 Angstroms.

Monochromatic output, or high frequency stability, is of great importance for lasers being used on interferometric measurements since the wavelength is the measure of length and distance and must be known with extreme precision, at least one part in a million, and it must remain constant with time. The same holds true for lasers used in chemical and many other scientific analytical applications. Both these techniques are important in quality control and inspection.

1.4 Coherence

The concept of coherence is one of considerable interest in a wide variety of laser applications such as holography, Doppler velocimetry and interoferometric measurements techniques useful in quality control. Lasers provide a high radiance source of light with a high degree of coherence. This combination is not available from any other source of light. There are two types of coherence, temporal, and spatial. Temporal coherence refers to correlation in phase at a given point in a space over a length of time. Coherence time is the time it takes a packet (photon) to pass a given point. Spatial coherence refers to correlation in phase at different points at the same time Of particular importance is the phase correlation on a surface transverse to the direction of propagation called a phase front. For a perfectly monocromatic wave this would be called a wavefront (e.g. the crest of water-wave) and all points would have the same phase. For lasers, phase fronts are spherical and the spatial coherence of the lasers operating in fundamental Gaussian mode is excellent.

1.5 Power Output

The output of a laser may be pulsed or continuous ( CW). Lasers used for quality applications usually have continuous output maintaining constant power output within narrow limits ± (1 – 2) % over a long period of time.