Short Description Of Projects

PAPER PRODUCTION FROM BAGASSE

Submitted By:

D.Das

Nikhil Rao

T.S.Srinivas

Course Instructor: Dr. Amit Ray

Introduction:

Sugar industry is among the largest traditional agro based industries in India. Bagasse is a major by-product of cane sugar production. It has been mainly used as fuel in boilers to raise steam. This practice is as old as the sugar industry when alternate applications of bagasse were not developed .Its use in boilers provided a means of captive consumption. Today bagasse should find better applications than burning in boilers. For example, it can be used for paper production. India produces about 1.8 million tonnes of paper annually presently. This is likely to increase by almost two fold during the next five year plan. About 80% of the raw material required for paper production comes for forest species like bamboo, soft wood etc. It is a common knowledge that for various reasons our forest cover is fast dwindling. This has caused an ecological crisis of alarming magnitude.

Conservation and afforestation efforts on a massive scale are urgently required to restore environmental balance. It is highly desirable to reduce pressure on forests by the consuming industries like paper mills by development of alternate technologies. The use of bagasse for paper production must, therefore, be encouraged to conserve forests. This can be achieved through a two fold strategy.

![]() Through energy

conservation efforts to be undertaken by

sugar mils

,substantial savings in bagasse are possible. As discussed elsewhere in this

report, the sugar industry is should make sincere efforts in this direction.

Through energy

conservation efforts to be undertaken by

sugar mils

,substantial savings in bagasse are possible. As discussed elsewhere in this

report, the sugar industry is should make sincere efforts in this direction.

![]() By supplying alternate

fuels to sugar mills, like natural gas ,entire bagasse can be saved and used for

production of paper or for any other application.

By supplying alternate

fuels to sugar mills, like natural gas ,entire bagasse can be saved and used for

production of paper or for any other application.

WHAT IS BAGASSE?

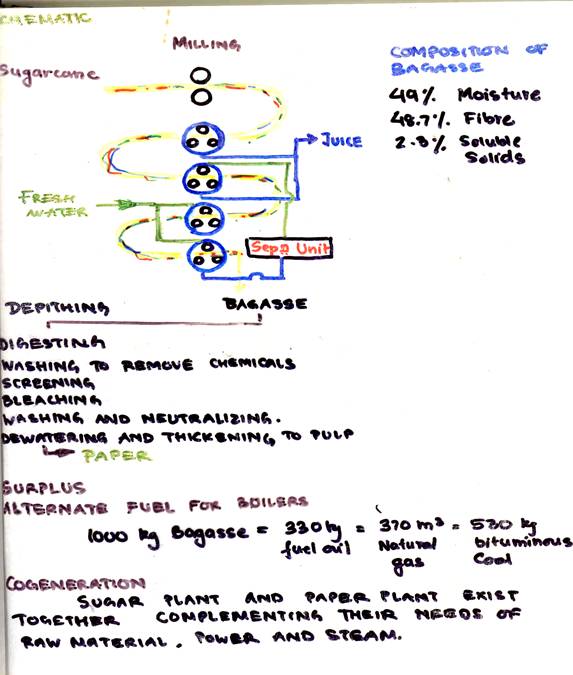

Bagasse is a fibrous residue left after the sugarcane is crushed in the sugar factories for extraction of juice. It contains about 48-50% moisture, 48% fibre and 2-4% sugar and other minor constituents. This is known as mill wet bagasse. The fuel value of bagasse is mainly by virtue of its fiber content, which in turn contains 45% cellulose, 28% pentosans , 20%.lignin and 5% sugar and 2% minerals. At 50% moisture, the gross heating value of mill wet bagasse is 2271 Kcal/Kg . The cellulose content of bagasse makes it viable as a fibrous raw material in the paper industry.

USE OF BAGASSE IN THE PAPER INDUSTRY:

For a long time, bamboo ,soft woods etc. had been the traditional fibrous raw materials in the paper industry throughout the world. But due to global shortage of these raw materials, the paper industry throughout the world had been exploring the possibilities of using alternate fibrous raw materials, particularly agricultural residues like bagasse. Toward the beginning of the current century, it was almost well established by paper experts throughout the world that bagasse, after proper depithing , was an ideal raw material for the manufacture of different kinds of paper, newsprint etc.

Unfortunately, most of the bagasse produced in India at present is burnt by sugar mills themselves, as fuel, to generate the steam required by the sugar mills. The typical consumption pattern of bagasse in India shows that 96-97%

CONCLUSION

From the survey we came to know that almost all of the consumer aware that pan masala an cause health problem and tried to stop but failed due to effects like headache, dizziness nd lost control during the period that they tried to stop. They start consuming it again s they could not withstand the effects. From this we infer that pan masala causes physilogical addiction not psychological.