Simulations at the Nanoscale Using Finite Element Method

Dr. Anandh Subramaniam, Department of Materials Science and Engineering

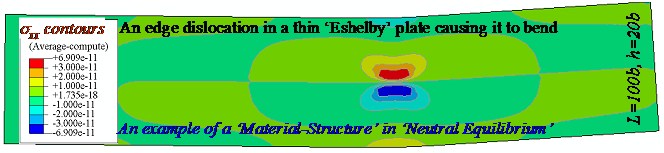

Finite Element Method (FEM) is not only a powerful tool for engineering analyses, but also for understanding the fundamental material behaviour at the nanoscale. In fact 'new phenomenon' and 'new materials' can be discovered using FEM simulations. This becomes possible because continuum behaviour can be retrieved at the lengthscale of even a few lattice spacing. Various structures and defects in crystals can be simulated and associated processes can be understood using FEM. These include: • Simulation of dislocations, epitaxial films, twins, grain boundaries, precipitates etc. • Study interactions between these defects • Formation of interfacial misfit dislocations in epitaxial thin films • Precipitation and coherent to semi-coherent transition of precipitates

Examples of parameters which can be computed from the simulations are: • Critical size for dislocation free nanocrystals • Image forces experienced by dislocations • Equilibrium critical thickness for the formation of misfit dislocations in a growing epitaxial film • Critical size for coherent to semi-coherent transition of precipitates

Usually significant improvement over existing analytical models is achieved: (i) in terms of ease of implementation and (ii) the correct analysis of the process.

Available computational facilities: computers and software (ABAQUS, Hypermesh, Mathematica etc.)

Keywords: Finite Element Method, Dislocations, Phase Transformations, Epitaxial films, Precipitation