Projects

Execution of innovative ideas and freedom to research is what we believe in.

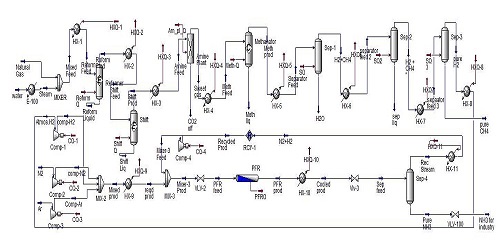

Ammonia Production

Aim is to carry out dynamic study of ammonia production for an industrial process. Increase conversion and cost minimisation by using heat integration and optimizing the process. Carried out literature survey for existing flowsheets for getting hydrogen from natural gas as well as for the Haber process. Explored for kinetics data i.e. pre exponential factors and activation energy for various reactions. First obtained hydrogen from natural gas and then coupling it with Nitrogen (from air) for Haber process. Optimizing the process parameters for maximizing conversion, selectivity and yield.

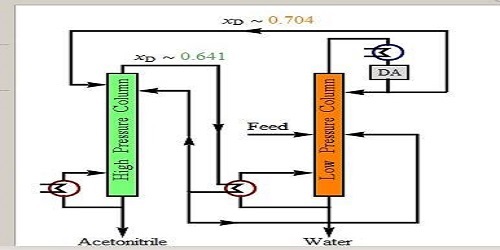

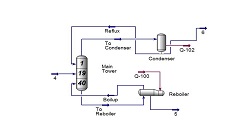

Azeotrope Separation

Designed Continuous Distillation Column for separation of mixture in MATLAB. Connect the two column one at high pressure and other at low pressure to separate out azeotrope mixture. Verified results obtained from MATLAB with ASPEN Hysys. Estimated composition at all trays using CMO approximation, mass and component balance. Carried out computation of VLE using Wilson’s model for activity coefficients.

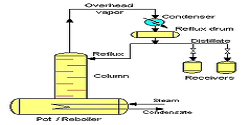

Batch Distillation

Designed Batch Distillation column for binary mixture of ethanol and water in MATLAB. Used Francis equation to calculate Liquid Flow Rate at each tray. Estimated composition at all trays by carrying out mass and enthalpy balances. Carried out computation of VLE using Wilson’s model for activity coefficients. Optimized the reflux ratio by computation of ideal number of trays.

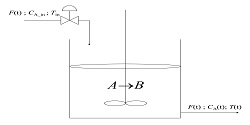

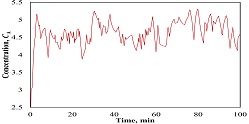

CSTR Modeling

Aim was to control the outlet concentration of reactant in the CSTR at a given set-point by manipulating the inlet flow rate. The computational intelligence (CI) based data-driven modeling technique genetic programming (GP) suggested which can search and optimize both the structure and parameters of a linear/nonlinear dynamic process model. The results of the GP-based identification when compared with those obtained using the transfer function based identification clearly indicates the outperformance by the former method.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Laminaire Prototype Design

This project’s idea was to assemble a device which converts the turbulence of the flow into steady, uniform crystal like flow, i.e., laminar flow. The device consisted of several components; it utilized porous material to remove eddies and reduced the turbulence parameter, i.e., Reynold’s number, using a set of straws. The flow inside the straws needs to achieve Reynolds no. of less than 2300 to be called laminar. This flow recombines and comes out of the system as a laminar streamlines. Remove(Apparently its Reynolds no. at the outlet is greater than 4600 – which is happening due to a completely different and interesting phenomenon)!!

.jpg)

.jpg)

Tar Removal

Aim was to clean and cool the producer gas which is producing from biomass (Sugarcane leaves and coconut shell). Various techniques implemented to remove dust and tar from producer gas like cyclone, Redmud packed bed, Absorption column, condenser column and Wet Electro-static Precipitator( WESP). Advanced cleaning system was also designed. Cleaned producer can be used in dual-fuel diesel engine.

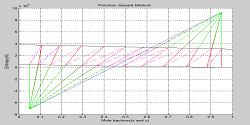

Binary Distillation Column Design

Optimized Continuous Distillation column for binary mixture of benzene and toluene in MATLAB using Ponchon savarit method and used different Vapor Liquid equilibrium method like – Ideal, Wilson and Chao-Seader method. Our future goal is design a multicomponent distillation column without taking assumption like- constant molar flow, constant relative volatility and Constant Pressure throughout the column.

.jpg)

.jpg)

.jpg)

Refrigerator

Designing an absorption refrigerator based on energy we get from cooling 100 kg of water at 80 degrees to room temperature. Right now working on design similar to one proposed by Adam Grosser in Ted 2007. Basic idea behind this is Icy Ball concept which was used in early twentieth century. Using that design as starting point, looking for refrigerants that can be used, which are cheap, non-hazardous and efficient. Currently working in collaboration with Nimbkar Agricultural Research Institute (NARI).

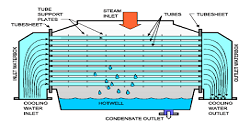

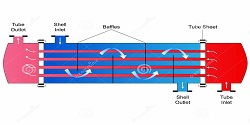

Heat Exchanger Design

MATLAB simulation for different types of heat exchangers were carried out i.e. Shell and Tube HX, Plate HX, Reboiler, Condenser etc. For the given fluids and temperature change requirements minimized operating cost plus capital cost to get the best possible output i.e. maximum possible heat exchange. Simulations were carried out for the two types of cost design parameters and different operating parameters such as pressure drop and heat consumption need to be kept in mind.

.jpg)

.jpg)

.jpg)

Heat Exchanger Prototype Design

A prototype was designed which can be fitted into a box of 40×10×10 cm3, minimized energy consumption to get maximized heat transfer. Explored the specific heat capacity data for the two liquids. Studied dynamics of the design i.e. temperature profiles and velocity profile of the two liquids. Used multiple software to simulate i.e. MATLAB, ANSYS Fluent, Aspen plus etc.

.jpg)

.jpg)

Water Purifier

Aim was to predict the status and the life of water purifier made up of activated carbon. To design a water filter, various methods were implemented in C, Fortran and Matlab. Mass transfer, adsorption and desorption coefficient were calculated by using experimental data. Future task is to convert this model in software.

© SimuTech Club, IIT Kanpur, Designed & Developed By Shivam Pal