Pipe Health Monitoring Robot (PHMR)

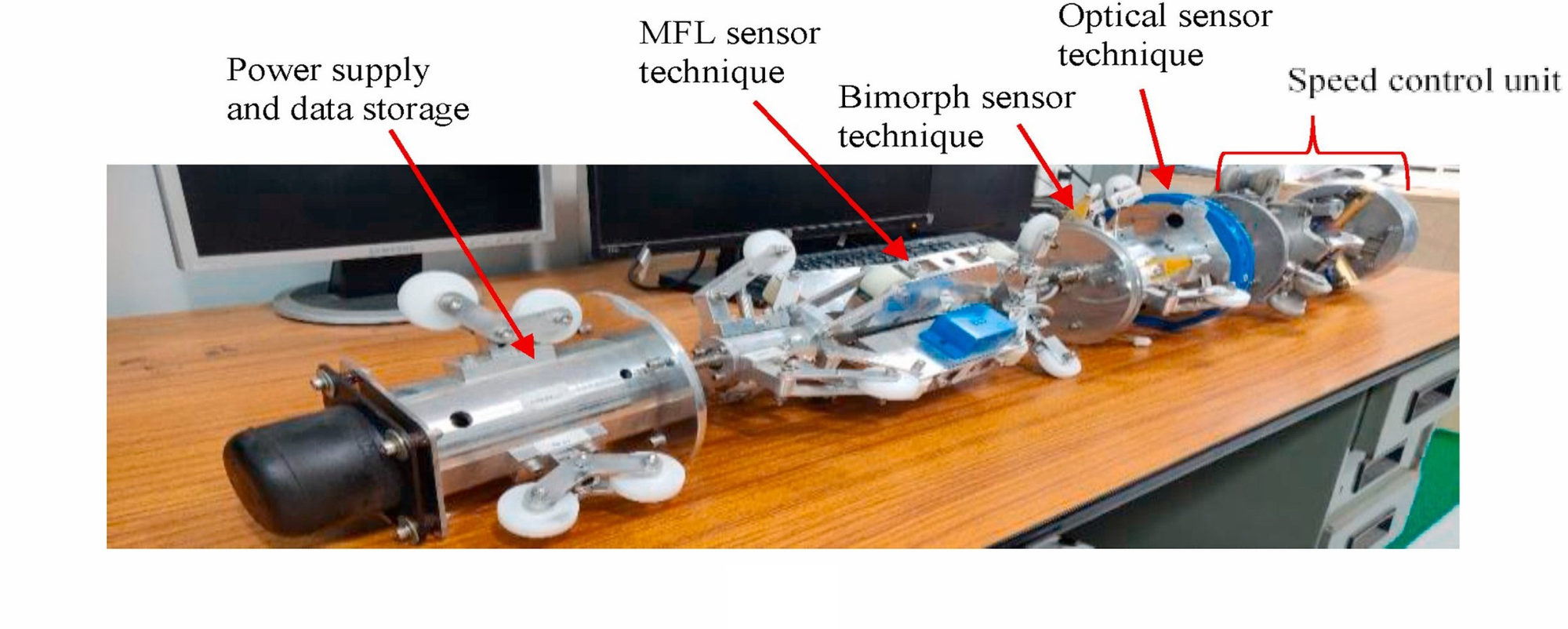

The project aims at developing a pipe health monitoring system based on smart sensors which can be transported inside compressed gas pipes with the help of a conduit crawler robot to determine the extent of anomalies present in the pipeline. The pipe health monitoring system will comprise a sensor network for anomalies detection, a micro-controller for processing the data from various sensor units and a storage unit to store the processed data, and an autonomous platform or robot, to carry these components inside the pipeline.

The entire duration of the project is 3 years and is divided into various phases of 6 months each with specific objectives. The first phase focuses on designing a new wheel assembly, optimising sensor parameters, data acquisition and pipe testbed automation. The second phase focuses on the robot design, GMR sensor, optimizing of optoelectronic sensor and parameter extraction. The third phase focuses on the final assembly of PHMR, design of touch probe, calibration of optoelectronic sensor and anomaly classification. The fourth phase focuses on defect position identification, sensor mounting, calibration of touch probe and user interface development. The final two phases involve testing the robot, communication system and final refinement.

Publications:

Patents: