|

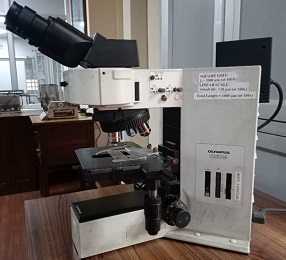

Optical MicroscopesMagnification: X50 to X1000 |

|

Optical Microscope - image analyzerMagnification: X50 to X1000 |

|

Mounting

Type: Hot Mounting |

|

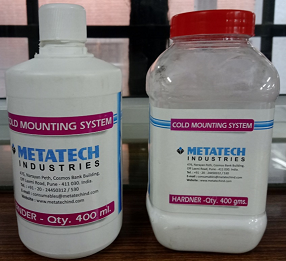

MountingType: Cold Mounting |

|

SectioningType: Low speed cutter |

|

SectioningType: High speed cutter |

|

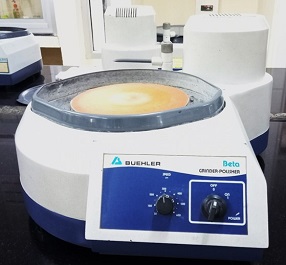

Polishing

Type: Cloth polishing |

|

PolishingType: Automated Cloth polishing |

|

Polishing

Type: Electro-polishing, Electro etching |

|

Heat TreatmentType: High temperature furnaceFurnaces: 3 tubular furnaces Temperature range: upto 1600°C Attachments: Temperature controller, Atmospheric controller Purpose: Heat treatment of metal |

|

Heat Treatment

Type: Low temperature furnace |

|

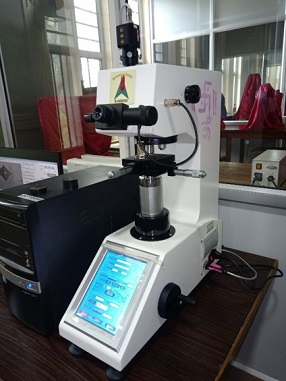

HardnessType: Vicker's micro-hardness |

|

Hardness

Type: Automated Rockwell hardness |

|

Grinding

Type: Abrasive belt grinding |

|

Grinding

Type: Abrasive belt grinding |

|

Hardness

Type: Vicker's micro-hardness |

|

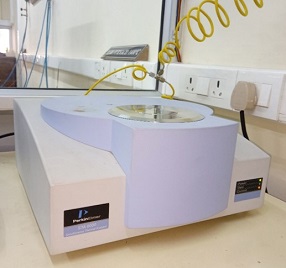

Differential scanning calorimetry

Type: simultaneous analysis of TG with DTA mode and DSC mode |