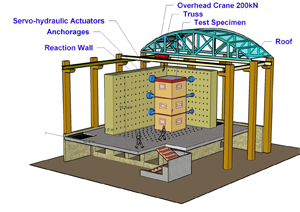

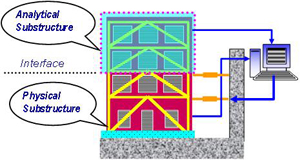

Pseudo-Dynamic (PsD) test method provides an affordable means to perform a fully dynamic test of a structure without the use of a shake table. The equations of motion of the test structure is integrated in the real time and computed deflections are applied to the structure at select points while system parameters of the test structure are updated in based on real time measurement of force-deformation characteristics. Explicit integration algorithms are used with appropriate provisions to ensure the overall stability of the test environment.

The ceiling height of the lab space is kept at 15 m to accommodate upto 10 m tall specimens and a 250 kN EOT crane. The integrated strong floor and wall provide a three-axis reaction frame system for application of vertical and lateral loads. The foundation slab of the three-cell box girder will provide a basement area for locating accumulators, manifolds for servo-hydraulic actuators.

PsD Apparatus

-

Non-yielding and stiff integrated reaction floor-wall assembly.

-

10x15x4.0 m three cell box girder floor and 10 m high, 2 m thick post-tensioned wall.

-

Anchorages at 0.6 m grid capable of 2 MN for axial load and 1.5 MN for shear loads.

-

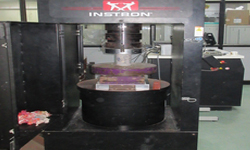

Closed Loop Servo Hydraulic actuator

MTS Series 201 hydraulic actuator, Model : 201.70

Stroke length: 1000 mm +/- 500 mm

Force: Tension: 965 kN

Compression: 1460 kN -

Self fabricated double girder E.O.T. crane

Capacity: 20 MT

Span: 21.65Meter

L.T speed: 12mpm

lift : 12 meter

Hybrid PsD using Substructures