APPLIED MECHANICS LABORATORY

Mechanics & Applied Mathematics group

Mechanical Engineering

Indian Institute of Technology Kanpur

We estimate forces during ploughing of a granular bed by performing experiments.

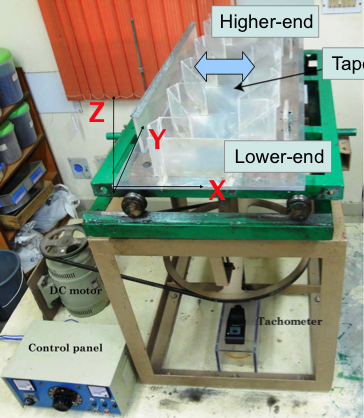

In our ploughing experiments in which a rigid, flat, inclined plough made of acrylic ploughs through a bed of steel balls. The system is shown in figure. The length and width of the channel are 1 m and 40 mm, respectively, and the depth of the plough’s cut is 70 mm. The bed is a mixture of steel balls having diameters of either 4 or 3 mm. The inclination angle of the plough is kept at 50 degrees. The plough is mounted with a load cell consisting of strain gauges that are used for measuring horizontal and vertical forces. The lead screw with pitch length of 2 mm is driven by a stepper motor. The plough is attached to the lead screw that travels along two guideways on either side. The plough moves at speeds between 1 and 18 mm per sec. Only a small amount of surcharge accumulates (lower inset of figure) as the steel balls spill over the channel’s sidewalls. The channel is made of acrylic so that the friction of the walls with the steel balls may be ignored. We estimated the internal friction angle of an aggregate of steel balls to be 21 degrees by measuring the angle of repose of a heap of steel balls.