| |

|

2-D PIV

|

2C-PIV is an optical technique which measures the velocity field in a plane. The flow field is seeded with tracer particles. A pulse laser with combination of cylindrical and spherical lens illuminates a plane with a laser sheet. The pulse separation is about nano-second which is adjusted depending on the magnitude of velocity measured. The laser is synchronized with a camera for acquisition of the image at same time instant. The cross correlation between two consecutive images provides the displacement of particles and the velocity. The 2C-PIV has been updated to stereo-PIV (3C-PIV) from support by Naval Research Board for measurement of all three components of velocity.

Technical Specifications:

Laser: Nd:YAG, New Wave

Laser Power: 15 mJ/pulse

Camera: PCO Sensicam 1280 X 1024 pixel

Synchroniser: Oxford Lasers

PIV Processing: Vid PIV

|

Location:

|

Fluid Mechanics Laboratory, RN: 301, Department of Mechanical Engg.

IIT Kanpur

|

Contact:

|

Prof. P. K. Panigrahi

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

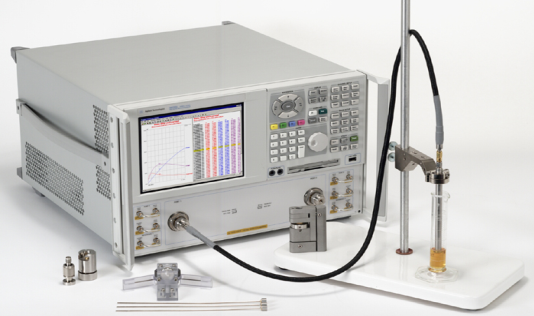

RF Analog Signal Generator Facility

|

Radio frequency signal generators (RF signal generators) are a particularly useful item of test equipment widely used in RF design and test applications. E8257D PSG analog signal generator delivers a sufficient level of output power, accuracy, and phase noise performance up to 20 GHz. The PSG analog signal generator's often eliminates the need of an external amplifier for testing high power devices and minimizes test uncertainty to identify errors early in the design process.

Unique features:

Signal Characteristics (250 kHz to 20GHz, 23dbm@20GHz), High SSB phase noise performance, Modulation (AM, FM, ØM, pulse, and scan), 8 ns rise/fall times and 20 ns pulse width, Dual internal function generators (sine, square, triangular), and Step, ramp sweep (frequency and power) etc.

|

Location:

|

Microwave Circuit Laboratory, Department of Electrical Engineering,

IIT Kanpur

|

Contact:

|

Prof. Kumar Vaibhav Srivastava

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

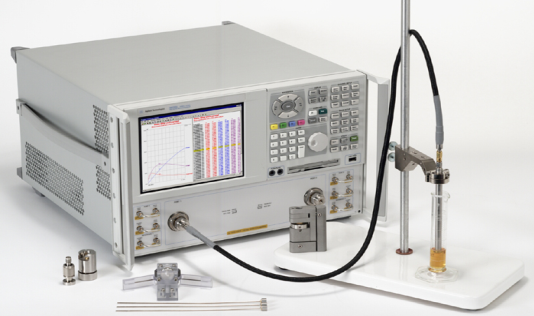

Fig: 1 Fig: 1

|

400 MHz NMR Machine with upgraded Console

|

Procures in the Financial Year: 2011-12 The machine is fully functional and is one of the most essential tools for structural characterization.

|

Location:

|

Core Lab 106b,

IIT Kanpur

|

Contact:

|

Prof. Ramesh Ramapanicker

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dr. Anand Singh

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

User Charges:

|

INR 10.00 per sample for 1H NMR

INR 25.00 per sample for 13C NMR

(Service tax is applicable for non-IITK users)

|

|

|

A Probe Station for Temperature and Magnetic Field Dependent Electrical measurements on thin films, devices and materials

|

Procures in the Financial Year: 2010-11

Capabilities:

Temperature dependent probe station with capabilities to make electrical measurements from 20K to 600K.

|

Location:

|

Western Lab – 105,

IIT Kanpur

|

Contact:

|

Prof. Ashish Garg

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

User Charges:

|

Rs. 1000/- per 3 hrs slot

(Service tax is applicable for non-IITK users)

|

|

|

Advanced Topometric Optical Sensor (ATOS)

|

Computer-aided techniques like CAD, CAM and FEM require an efficient coordinate measuring technique in order to achieve exact correspondence between numerical model and real component. Using the digitizing system ATOS (Advanced Topometric Sensor), an object can be measured in a short time and with high local resolution. Each single measurement generates up to 1.3 million data points. The individual measurements are merged into a project and the measured data can be exported as point clouds, sections or STL-data. Additional hardware, such as mechanical measuring machines, translation units or robots, is not required.

Features:

The user can concentrate on the digitizing progress as all the transformations are performed automatically by the system.

The same sensor (ATOS XL) is capable of measuring small and large objects (10mm up to 10m).

Due to the high point density, details of the component can be depicted precisely. The accuracy of the measured data is comparable to that of single frame coordinate measuring machines.

The system can be transported in two flight cases (part of the standard equipment) by car or plane

|

Location:

|

CAD Lab, Department.of Mechanical Engineering,

IIT Kanpur

|

|

Air Cooled Chiller

|

A chiller is a machine that removes heat from a liquid via a vapor-compression or absorption refrigeration cycle. A vapor-compression water chiller comprises the 4 major components of the vapor-compression refrigeration cycle (compressor, evaporator, condenser, and some form of metering device). The chiller will be used to fed the PECVD/ Sputtering systems etc.

|

Location:

|

NET building, Department.of Mechanical Engineering

IIT Kanpur

|

Contact:

|

Prof. Shantanu Bhattacharya

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Artec MHT™ 3D Scanner

|

The Artec MHT scanner captures brilliant color at up to 24 bits per pixel. That means that the resulting texture is of great quality similar to a modern video camera. This model is perfect for designers, movie makers and animators. Also, this is a great tool for those in the heritage preservation industry, because capturing the enchanting coloring of a clay pot from ancient Greece is just as important as capturing its shape. This is the appropriate choice for those that need to not only acquire 3D data, but the color of the object as well.

Heritage Preservation

Artec 3D Scanners are portable, phenomenally quick and can be used with objects of various sizes. There’s no need to move scanned items or to place markers on the object. These are the advantages that make our 3D Scanners an indispensable tool in the preservation of the world’s cultural heritage.

Restoration

Restoration of interiors and entire buildings means reproducing missing features of the decor. This means obtaining exact 3D copies of features of sculpture, architecture, stucco ornaments or fragments of antique furniture. Artec 3D Scanners enable users to carry out these tasks with ease and concentrate on producing the items needed in order to restore the original look.

Archives and catalogues

The Artec 3D Scanner can be used to make copies of items found in the course of archaeological or palaeontological work, such as fragments of ceramics or bone. This means databases can be set up and made accessible to researchers.

|

Location:

|

CAD Lab, Department of Mechanical Engineering,

IIT Kanpur

|

AMBIOS Surface Profilometer

|

Ambios Profilometer is a computerized, high- sensitivity surface profiler that measures roughness and step height in a variety of applications. It features the ability to measure precision step heights from under 10 Angstroms to as large as 1.2 millimetres. The profiler incorporates a new optical deflection height measurement mechanism and magneto static force control system that results in allow force (loads as small as 0.03mg) and low inertia stylus assembly. These innovations combine to produce a surface profiler capable of measuring soft films and substrates without surface damage. Simply position your sample on the scan stage, select a scan recipe, click the scan button, and as soon as the scan is complete, your surface data is immediately available for analysis. The XP-100 Profilometer provides an affordable, high resolution surface measurement capability that nicely complements other analytical instruments.

Profilometer provides following features:

-

Scan Length range- 30mm maximum

-

Sample Thickness -20mm

-

Vertical resolution- 100nm

-

Vertical range -1200um maximum

-

Step height repeatability 5Ao

-

Repeatability: approx 1um step height

-

Sample view camera- colour camera

-

Standard magnification- 100X

-

Stylus tip radius -2.5um

-

Stylus force range -0.03-10mg

|

Location:

|

Clean Room - P2, Samtel Center for Display and Technology (SCDT),

IIT Kanpur

|

Contact:

|

Mr. Dharmendra Swain

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Atomic Absorption Spectrometer

|

The Atomic absorption (AA) spectrometer is used to analyze metals at very low concentrations, typically in the parts per million (ppm) or parts per billion (ppb) ranges. A liquid sample containing dissolved material whose concentration is to be measured is aspirated into a thin, wide AA flame, or is introduced into a small carbon furnace which is heated to a high temperature. The Atomic absorption (AA) spectrometer (Varian AA240) (Figure 1) was established in the Core Lab (201D) in 2007 with the DRDO grant of the Institute.

Basic Principle:

AAS is the measurement of absorption of radiation by free atoms. The total amount of absorption depends on the number of free atoms present and the degree to which the free atoms absorb the radiation. At the high temperature of the AA flame, which may be either oxy-acetylene as used here, or nitrous oxide/acetylene, the sample is broken down into atoms and it is the concentration of these atoms that is measured (Figure 2).

Unique Features:

Fast Sequential capabilities with four lamps, so we can determine more elements in rapid sequence from one sample analysis. Fully automatic wavelength and slit selection simplifies operation, even for novice users. Completely sealed optics with quartz overcoated mirrors offer protection in dusty or corrosive environment. The air purge system is fitted inside the instrument eliminating the chance of corrosion in rugged or corrosive environments.

|

Location:

|

Department of Chemical Engineering, Core Lab 201D,

IIT Kanpur

|

Contact:

|

Prof. Nishith Verma

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Figure 1

|

Figure 2

|

Atomic Force Microscope

|

Atomic Force Microscope and is often called the "Eye of Nanotechnology". AFM is a high- resolution imaging technique that can resolve features as small as an atomic lattice in the real space. It allows to observe and manipulate molecular and atomic level features. This AFM is capable of scanning large areas with high resolution. Conducting AFM, MFM, imaging in liquid media, atomic level manipulations, dip pen lithography and local anodic oxidation are some of the salient features of this microscope

|

Location:

|

Thematic Unit of Excellence,

IIT Kanpur

|

Contact:

|

Prof. Ashutosh Sharma

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dr. Prabhat Dwivedi

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dr. Dinesh Deva

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Atomic Force Microscopy facility (Park XE 70)

|

Users desirous of using the facility may fill up the booking form available at http://home.iitk.ac.in/~sar/AFM_CARE2013.pdf. A new Atomic Force Microscopy facility has been established under the CARE funding 2013 and is now operational. The AFM is a Park XE 70 machine with a 100micron X 100 micron scanner head and a liquid cell.

Application:

Accurate XY Scan by Crosstalk Elimination

-

Independent, loop XY and Z flexure scanners for sample and probe tip

-

Flat and orthogonal XY scan with low residual bow

-

Out of plane motion of less than 2 nm over entire scan range

-

Accurate height measurements without any need of software processing

Best Life, by True Non-ContactTM Mode

-

10 times faster Z-servo speed than competing AFM piezo tube

-

Less tip wear for prolonged high-quality and high-resolution imaging

-

Minimized sample damage or modification

-

Immune from parameter-dependent results observed in tapping imaging

The Most Extensible AFM Solution

-

The most comprehensive range of SPM modes

-

The largest number of sample measurement options

-

The best option compatibility and upgradeability in the industry

The Best User Convenience by Design

-

Open side access for easy sample or tip exchange

-

Easy, intuitive laser alignment with pre-aligned tip mount

-

Easy head removal by dovetail-lock mount

-

Direct on-axis optics for high resolution optical viewing

Features:

|

User Charges: :

|

Rs. 1000 for 2 hours A user fee of Rs.1000 for a 2 hour slot will be applicable.

|

Location:

|

Department of Physics

IIT Kanpur

|

Contact:

|

Prof. S. Anantha Ramakrishna

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

BET Surface Area & Pore Volume Analyzer

|

Quanta chrome Autosorb 1C BET Surface Area & Pore Volume Analyzer is an instrument to determine the specific surface area of powders, solids and granules, the values are expressed in meter square per gram, pore size analysis, micropore analysis, pore size distribution by pore diameter, pore volume and pore surface area. The Quanta chrome Autosorb 1C BET Surface Area & Pore Volume Analyzer (Figure 1) was established in the Core Lab (201D) in 2009 with FIST (DST) grant of the Institute.

Basic Principle:

The adsorption/desorption isotherms and pore volumes of the adsorbents were determined by nitrogen adsorption–desorption isotherms, measured at 77 K using Quanta chrome Autosorb 1C system. The samples were degassed at 200°C under vacuum before starting N2 adsorption. Surface area and pore volumes (or pore size distribution) were determined using the Brunauer–Emmet–Teller (BET) equation, Barret–Joyner–Halenda (BJH) and DFT methods respectively.

Unique Features:

Automatically performed Temperature programmed techniques (TPR/TPD/TPO. Flow-based, pulse titration method for rapid determination of active surface area, degree of metal dispersion. Available vapor generator option with heated manifold for use with water and organic vapors. Available, integrated mass spectrometer option for identification of desorbed gases. High sensitivity, thermal conductivity detector (TCD) for TPR/TPD/TPO analysis and automatic physisorption and chemisorption by precise vacuum volumetric method for analysis of BET surface area, meso- and micropore size distribution, active surface area, degree of metal dispersion, heats of adsorption, etc.

|

Location:

|

Department of Chemical Engineering, Core Lab 201D,

IIT Kanpur

|

Contact:

|

Prof. Nishith Verma

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Figure 1

|

Figure 2

|

Brewster Angle Microscope

|

EP3-BAM is an ideal thin films imaging system. It is a completely "hands-off" computer-controlled system, using proprietary motor control circuitry. The EP3-BAM displays real-time image of your sample directly on the monitor and features important image processing functions. An "objective scanner" provides extended depth-of- field for overall-focused images. The combination of a high power green laser and excellent objectives allows lateral resolutions of 1 micron, the current limit of CCD optical detectors. The powerful software makes operation easy and convenient. As a complete solution, the system comes including the computer, electronics, and all necessary software needed to begin measurements on your existing trough, or with one of our integrated NIMA troughs

|

Location:

|

Thematic Unit of Excellence,

IIT Kanpur

|

Contact:

|

Prof. Ashutosh Sharma

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dr. Prabhat Dwivedi

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dr. Dinesh Deva

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

CAMAG HPTLC System with AMD2

|

High Performance Thin Layer Chromatography is capable of separating organic compounds. Automated multiple development adds flexibility and enhance reproducibility and quantification. The user need to have knowledge of layers and solvents to be used for separation. In the absence of this knowledge, a method development step is necessary. The sensitivity of thin layer chromatography is less than gas or liquid chromatography. However, it is fast, standards and samples can be analyzed simultaneously on the same plate, versatile about the sample solvent and cheapest amongst all the chromatographic applications

Technical Specifications:

Components available are: Linomat 5 for sample application, AMD2 for automated multiple development, twin trough tanks of different sizes for manual single solvent developments, HPTLC vario system for method development, TLC Scanner 3 for detection, TLC/HPTLC documentation system with digital camera, Reprostar TLC/HPTLC viewing box with UV system, TLC plate heater, TLC plate coater, dip tanks, dedicated computer with win CATS Planar Chromatography System Manager.

|

Location:

|

Environmental Engineering Laboratory, WL 116

IIT Kanpur

|

Contact:

|

Prof. Saumyen Guha

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Chemical Balance

|

A beam balance of great precision used in quantitative chemical analysis.

|

Location:

|

NET building, Department.of Mechanical Engineering

IIT Kanpur

|

Contact:

|

Prof. Shantanu Bhattacharya

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

| |

Procures in the Financial Year: 2011-12

The machine "Contact Angle Goniometer" is designed to investigate interfacial properties (surface free energy, wettability, surface/interfacial tension) of solid-solid, solid-liquid and liquid-liquid interface. The machine is designed with four software controlled dosing unit (electronic syringes) to eject controlled amount of various liquids on a solid surface. The machine has normal as well as high speed imaging capability to explore static and dynamics of interfacial properties. It also has an environmental chamber to manipulate environmental conditions e.g. temperature, humidity, gas and study its effect on interfacial properties.

|

Location:

|

Southern Lab 20,

IIT Kanpur

|

Contact:

|

Prof. Krishnacharya

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

User Charges:

|

For a 2 hour slot:

Contact angle/surface tension measurement (ambient condition) INR. 200/-

Interfacial tension (between two fluids) measurement (ambient condition) INR. 500/-

Surface free energy of solid measurement (ambient condition) INR. 1000/-

Measurement involving environmental chamber (variable temp, humidity) INR. 2000/-

Measurement involving high speed camera (upto 1000 fps) INR. 2000/-

(Service tax is applicable for non-IITK users)

|

|

|

Contact Angle Tensiometer Facility

|

Model OCA EC15 from Data Physics, GmbH, Germany

Surface properties such as wetting behavior, surface free energy and its polar and dispersion components significantly affect the end use of the material in numerous ways. Some of the examples are hydrophobicity ND hydrophilicity of implanted material that affect cell adhesion, surface energy that affects spreading of liquid ink in printable electronics, adsorption behavior of packaging material in food packaging industry, etc. Therefore, it is necessary to evaluate the surface properties of engineering material.

Specifications:

Dosing volume up to 0.1μl; Temperature variation (5-90°C); Advancing and receding contact angle measurement (-20 to 70°); OCA 23 software equipped with surface energy calculation; Large database of scientific liquids; adsorption rate of liquid on specimen; contact angle between two immiscible liquids.

|

Location:

|

Biomaterials Processing & Characterization Laboratory (behind Western Laboratories)

IIT Kanpur

|

Contact:

|

Prof. Kantesh Balani,

This email address is being protected from spambots. You need JavaScript enabled to view it.

,

|

|

Control Systems Laboratory

|

Facilities:

18 benches, each with

- A permanent magnet dc motor control setup built around a dsPIC30F4012 microcontroller

- Function generator

- Power supply

- PC with MPLAB IDE, GNU Octave, etc.

Each setup is capable of communication with the remaining setups using Controller Area Network (CAN) protocol. This experimental setup was developed in the NCS Laboratory.

|

Location:

|

Department of Electrical Engineering

IIT Kanpur

|

Contact:

|

Prof. Ramprasad Potluri

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

CARL ZEISS AXIO IMAGER A1m RESEARCH TRINOCULAR REFLECTED LIGHT MICROSCOPE FOR BRIGHT FIELD, CIRCULAR DIC.

|

The AxioImager A1m microscope features the EC Epiplan-Neofluar Lens, which supplies substantially more visible information, and the Differential Interference Contrast in Circular polarized light (C-DIC) contrasting technique that makes all image information visible without stage rotation, in addition to providing greater contrast and image clarity. (NO TRANSMISSION IMAGE FACILITY & CAMERA ATTACHMENT

Minimization of stray light components that reduce contrast are created by residual reflections of the lens surfaces and reflections at the edge of the mount. Via specific target functions in the optics correction procedure that influence the rest of the optical imaging procedure for lens surface reflections, and through careful selection of antireflection coatings, the residual light components created by single and multiple reflections on the lens surfaces are manipulated so that they can no longer have a significant effect on the contrast in the image plane.

Special features:

Axio Imager. A1m microscope stand incl. Z-drive man., reflected-light illumination with aperture stop and luminous-field diaphragm, with DIC Objectives: Epiplan5x/0.13DIC M27(a=15.8mm), 10x/0.25DIC M27(a=9.3mm), 20x/0.22 M27 (a=12.1mm), 50x/0.55 DIC M27 (a=9.1mm), 100X on Order, and Eyepiece 10x/23 Br. Foc

|

Location:

|

Optoelectronics Laboratory, Department of Electrical Engineering,

IIT Kanpur

|

Contact:

|

Prof. Utpal Das

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Cary 5000 UV-Vis-NIR Spectrophotometer

|

The Cary 5000 can be used to achieve significant performance breakthroughs across a range of applications; from simple optical absorbance and reflectance measurements in the wavelength range (175-3300 nm) for solid and liquid samples to quantifying out-of-band blocking characteristics of band pass filters and also measuring the high transmission of next generation fibre optic materials.

Salient Features:

Wavelength Range 175-3300 nmOptical Isolation System Solid aluminium casting that isolates the optics from external disturbances. i.e. laboratory environment won't affect your instrument's performance. Pb smart technology where PbS NIR detector provides best noise and linearity performance Schwarzchild Coupling Optics: Ensures the maximum level of light throughput resulting more accurate measurements at low transmission levels Variable and Fixed slits: Allows optimum control over data resolution. The spectral bandwidth can be set down to 0.01 nm. The slits can be fixed in the NIR as well as the UV-Vis regions Out-of-plane double Littrow monochromator Minimizes photometric noise and stray light, providing excellent resolution Advanced electronics design: The instruments can typically measure beyond 8 Abs with reference beam attenuation Nitrogen purging: Monochromator and sample compartments have separate nitrogen purging capabilities, allowing the sample compartment to be purged at a higher rate than the instrument. Praying Mantis Diffuse Reflection Accessory (DRA) Praying Mantis is the diffuse reflectance accessory that is used for easy and reliable diffuse reflection analysis of solids and powders. It incorporates two 6:1, 90° off-axis ellipsoids which form a highly efficient diffuse reflection illumination and collection system. This unique configuration deflects the specular reflectance away from the collecting ellipsoid, minimizing the associated spectral distortions. The Praying Mantis also can be configured to study materials and reactions in controlled environments with the appropriate diffuse reflectance reaction chamber.

|

Location:

|

Department of Chemical Engineering, CL 201B

IIT Kanpur

|

Contact:

|

Prof. Goutam Deo

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Figure: 1

|

Figure: 2

|

Figure: 3

|

Cary 5000 UV-Vis-NIR Spectrophotometer

|

The Cary 5000 can be used to achieve significant performance breakthroughs across a range of applications; from simple optical absorbance and reflectance measurements in the wavelength range (175-3300 nm) for solid and liquid samples to quantifying out-of-band blocking characteristics of band pass filters and also measuring the high transmission of next generation fibre optic materials.

Salient Features:

Wavelength Range 175-3300 nmOptical Isolation System Solid aluminium casting that isolates the optics from external disturbances. i.e. laboratory environment won't affect your instrument's performance. Pb smart technology where PbS NIR detector provides best noise and linearity performance Schwarzchild Coupling Optics: Ensures the maximum level of light throughput resulting more accurate measurements at low transmission levels Variable and Fixed slits: Allows optimum control over data resolution. The spectral bandwidth can be set down to 0.01 nm. The slits can be fixed in the NIR as well as the UV-Vis regions Out-of-plane double Littrow monochromator Minimizes photometric noise and stray light, providing excellent resolution Advanced electronics design: The instruments can typically measure beyond 8 Abs with reference beam attenuation Nitrogen purging: Monochromator and sample compartments have separate nitrogen purging capabilities, allowing the sample compartment to be purged at a higher rate than the instrument. Praying Mantis Diffuse Reflection Accessory (DRA) Praying Mantis is the diffuse reflectance accessory that is used for easy and reliable diffuse reflection analysis of solids and powders. It incorporates two 6:1, 90° off-axis ellipsoids which form a highly efficient diffuse reflection illumination and collection system. This unique configuration deflects the specular reflectance away from the collecting ellipsoid, minimizing the associated spectral distortions. The Praying Mantis also can be configured to study materials and reactions in controlled environments with the appropriate diffuse reflectance reaction chamber.

|

Location:

|

Department of Chemical Engineering, CL 201B

IIT Kanpur

|

Contact:

|

Prof. Goutam Deo

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Figure: 1

|

Figure: 2

|

Figure: 4

|

Cyclic Triaxial Testing System to Evaluate Shear Strength and Liquefaction Potential of Noncohesive Soils

|

The triaxial cyclic loading frame is designed as a stand unit in which the mechanics, pneumatic as well as the necessary electronic interface to the computer have been installed. Cyclic triaxial test is capable of applying a uniform sine, square and triangular load at a frequency within the range of 0.001 Hz to 100 Hz. The cyclic triaxial test consists of imposing either a cyclic axial deviator stress of fixed magnitude (load control) or cyclic axial deformation (stroke control) on a cylindrical soil specimen enclosed in a triaxial pressure cell. The result of axial strain and axial stress are measured and used to calculate either stress dependent or stroke-dependent modulus or damping. The cyclic triaxial modulus or damping test provides parameter that may be considered for use in dynamic, linear and non linear analytical methods. One of the primary purposes of these test method is to obtain data that are used to calculate Young’s modulus and Liquefaction Potential.

|

Location:

|

Department of Civil Engineering,

IIT Kanpur

|

Contact:

|

Prof. Nihar Ranjan Patra

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Data Mining Laboratory

|

Features:

Hardware:

-

High-end computers

-

High-end Color Printers

-

Video Camera

MATLAB

MATLAB (MATRIX LABORATORY) the high-performance language for technical computing. We have the compilers, plus toolboxes for image processing, optimization, signal processing, simulink, state flow, wavelets, and control.

|

Location:

|

Department of Electrical Engineering

IIT Kanpur

|

Contact:

|

Prof. Nishchal K. Verma

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Deep Reactive Ion Etch (DRIE) System

|

The Deep Reactive Ion Etching (DRIE) system was procured in 2009 with financial support from IIT Kanpur. This enables making structures in silicon, and is housed in the Centre for Environment Sciences and Engineering.

Unique Features:

An inductively coupled plasma (Figure 1) results in generation of ions and radicals which play a role in etching silicon and maintaining the required profile. The process feed gases include SF and Fluorine 6radicals and ions from SF react with the silicon surface to form volatile SiFx species and are responsible for etching. 6As the isotropic nature of the fluorine radicals would result in an isotropic etch profile, the polymerizability of CF is 48used. The radicals generated from CF deposit on the silicon surface and while the sidewalls are protected from 48lateral etch, the subsequent directional F ions remove these from the etch front for subsequent etch propagation. In the system, SF and CF are pulsed alternately into the reaction chamber which enables anisotropic etched profiles.

|

Location:

|

Center for Environmental Science and Engineering,

IIT Kanpur

|

Contact:

|

Prof. Siddhartha Panda

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Desk Top Mask Aligner

|

Mask aligners are used in most microfabrication research laboratories and in even in low- volume production facilities. Almost any microscale device or structure requires more than one photomask step. The job of the contact aligner is to allow its user to align features on a substrate (wafer) to features on a photomask. The production of sophisticated electronic devices may involve ten or more of these alignment steps.

|

Location:

|

NET building, Department.of Mechanical Engineering

IIT Kanpur

|

Contact:

|

Prof. Shantanu Bhattacharya

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

De-ionized Water Plant with Water testing equipment

|

(a) The De-ionized water Plant comprises of two Units, the CA-20 and the MB-25. Tap water first passes through the CA-20 plant which lowers the ppm value to 10ppm. This water then passes through the MB-25 plant, which makes the water de-ionized with 0 ppm and conductivity 0 μS/cm . The meters measure in steps of 0, 10, 20, …1990 ppm or μS/cm.

(b) Water Testing equipment

- Oakton Instruments water-proof TDS tester. It can detect impurity of water from 0

to 1990 ppm, with a resolution of 10ppm. It has an automatic temperature compensation function.

- Oakton Instruments water-proof conductivity tester. It can detect conductivity from 0 to 1990 μS/cm, with a resolution of 10 μS/cm.

- pH value testing of the de-ionized water using Litmus paper.

- Testing of impurities in the de-ionized water using Chemical Setup, comprising of Silver nitrate and Nitric Acid.

This is an in-house facility and cannot be borrowed out of the Lab.

Use On Payment basis - for details see Forms in http://www.iitk.ac.in/ibc/

|

Location:

|

Ion Beam Complex, NL-105, Department of Physics, IIT Kanpur.

|

Contact:

|

Co-ordinator, IBCOR

Mr. S. Krishnasamy

Technical Superintendent, IBC

(

This email address is being protected from spambots. You need JavaScript enabled to view it.

).

Phone: 7986 / 6993

|

Figure: 1

Figure: 2

|

DI Water System

|

Distilled water is perfect for applications where minerals and contaminants would cause problems. Distilled water can be used in irons for steam settings or as coolant for car engines. Because there are no minerals that can stain or build up, distilled water is mostly recommended for use in machinery and cleaning products. The system produces Distiller water by heating and vaporization followed by collection and condensation of the vapours.

|

Location:

|

NET building, Department.of Mechanical Engineering

IIT Kanpur

|

Contact:

|

Prof. Shantanu Bhattacharya

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Dicing Saw

|

A dicing saw employs a high-speed spindle fitted with an extremely thin diamond blade to dice or groove semiconductor wafers and other work-pieces.

|

Location:

|

NET building, Department.of Mechanical Engineering

IIT Kanpur

|

Contact:

|

Prof. Shantanu Bhattacharya

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Digital Signal Processing Laboratory

|

Facilities:

The software facilities include the following:

-

Code Composer Studio

-

MatLab

-

LabVIEW

Test and measuring instruments:

Computers include various software and applications

-

Intel Quad Core Desktop Computer

-

Intel Pentium IV Desktop Computer

-

Intel Core I7 Desktop Computer

|

Location:

|

Department of Electrical Engineering

IIT Kanpur

|

Contact:

|

Prof. Adrish Banerjee

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Dynamic High-Resolution Polarized Inverted Laser Confocal Fluroscence Microscopy

|

Procures in the Financial Year: 2010-11

-

Inverted Microscope

-

Confocal and reflected mode operation

-

Individually controllable continuous wave lasers

-

Ar, 65mW: 458, 476, 488, 514 nm;

-

HeNe, 20 mW: 543: Green

-

HeNe, 2 mW: 633: Red

-

Multi-dimensional image capture in Space (X,Y,Z) and time (t)

-

Conventional scanning at 5 FPS at 512 X 512 pixels to 54 fps at 512 x 16 pixels

-

Typical resolution in X, Y : 200 nanometers

-

Maximum depth of view Z (depends on the objective): about 1000 microns

-

Three channel Spectrometer detector for high quality spectral image series

-

Polarizer-Analyzer Attachment

|

Location:

|

Micro-fabrication Laboratory, NL-1, Department of Mechanical Engineering,

IIT Kanpur

|

Contact:

|

Prof. P. K. Panigrahi

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

User Charges:

|

Free

Note: A slot has to be booked for using the machine

|

|

|

Dielectric Measurement Facility

|

The material characterization facility in the microwave frequency band was established in the Department of Electrical Engineering in the year 2010 with CARE grants from IIT Kanpur. The facility is based on the Agilent Technologies 85070E Dielectric Probe Kit, which comes along with the vector network analyzer and associated microwave components. The established facility enables one to determine the dielectric properties or the complex permittivity of wide range of materials in the broad frequency range of 200 MHz to 20 GHz. As the dielectric properties of materials are related with their molecular structure, the measurement of dielectric properties leads to much other useful information which is otherwise quite difficult to obtain. This facility (Fig. 1) is currently installed in the Microwave Imaging and Material Testing Laboratory of the department. The facility is expected to be used by departments of Civil Engineering, Bio Engineering, Material Science and Engineering, apart from the host department.

Unique features:

The dielectric probe kit is one of the most useful methods for electromagnetic characterization of materials in the broad frequency range. The complete system is based on a network analyzer, which measures the material’s response to RF or microwave energy. The probe transmits a signal into the material under test (MUT), and the reflected data is used to determine the dielectric properties of the MUT using a special software, which is supplied along with the kit. The software controls the network analyzer and guides the user through easy setup and measurement procedures. The complex permittivity of the test sample is finally displayed on screen using the supplied software.

|

Location:

|

Microwave Imaging and Material Testing Laboratory, Department of Electrical Engineering,

IIT Kanpur

|

Contact:

|

Prof. M. Jaleel Akhtar

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Dielectric probe kit for determination of electromagnetic properties over a wide band of frequencies

|

The dielectric measurement facility in the microwave frequency band was established in the Department of Electrical Engineering in the year 2010 with CARE grants from IIT Kanpur. The facility is based on the Agilent Technologies 85070E Dielectric Probe Kit, which comes along with the vector network analyzer and associated microwave components. The established facility enables one to determine the intrinsic electromagnetic properties of wide range of materials in the broad frequency range of 200 MHz to 20 GHz. As the dielectric properties of materials are related with their molecular structure, the measurement of dielectric properties leads to much other useful information which is otherwise quite difficult to obtain. These properties are usually expressed in terms of permittivity and permeability, which might change with frequency, temperature, orientation, mixture, pressure etc. The electromagnetic characterization facility using the dielectric probe kit is currently installed in the Microwave Imaging and Material Testing Laboratory of the Electrical Engineering department as shown in Fig. 1. The facility is expected to be used by departments of Civil Engineering, Bio Engineering, Material Science and Engineering, apart from the host department. The dielectric probe kit is one of the most useful methods for electromagnetic characterization of materials in the broad frequency range. The complete system is based on a network analyzer, which measures the material’s response to RF or microwave energy. The probe transmits a signal into the material under test (MUT), and the reflected data is used to determine the dielectric properties of the MUT using special software, which is supplied along with the kit.

|

Location:

|

Department of Electrical Engineering,

IIT Kanpur

|

Contact:

|

Prof. M. Jaleel Akhtar

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Differential Scanning Calorimetry/Thermogravitometry/Differential Thermal Analyzer (STA8000)

|

-

Compositional analysis – quantitative content analysis

-

Melting/crystallization behavior

-

Decomposition temperatures

-

Glass transition temperatures

-

Engine oil volatility measurements (TGA Noack test)

-

Specific heat capacity

-

Filler content

-

Kinetic studies

-

Flammability studies

-

Transition and reaction enthalpies

-

Lifetime predictions (via TGA kinetics software)

-

Measurement of volatiles (e.g., water, oil)

-

Oxidative stabilities

-

Thermal stabilities

-

Catalyst and coking studies

-

Hyphenation to identify out-gassing products range:

Temperature:

15 °C to 1000 °C

Balance resolution:

0.1 ug

Balance measurement range:

Up to 1500 mg

Heating rate:

Ambient to 1000°C and Cooling rates: from 1000 °C to 30 °C Under

|

Location:

|

WL210, Department of Materials Science & Engineering,

IIT Kanpur

|

Contact:

|

Prof. Krishanu Biswas

kbiswas@ iitk.ac.in

|

|

E-beam Vacuum Coating Unit – Currently Being Installed

|

Turbo pump + Mechanical Pump to 10-7 torr, 6kW e-beam, 4 –Turret with indexer.

Special features:

Digital Thickness Monitor, Turret indexer, Programmable Sweep

|

Location:

|

Optoelectronics Laboratory, Department of Electrical Engineering,

IIT Kanpur

|

Contact:

|

Prof. Utpal Das

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Elemental Analyzer

|

Elemental analysis is an experiment that determines the amount (typically a weight percent) of an element in a compound. A CHN/O Analyzer is a scientific instrument which can determine the elemental composition of a sample. The name derives from the three primary elements measured by the device: carbon (C), hydrogen (H) and nitrogen (N) and oxygen (O). Sulfur (S) can also be measured. The Elemental Analyzer (Exeter Analytical Inc. model: CE 440) (Figure 1) was established in the Core Lab (201D) in 2007 with the DRDO grant of the Institute.

Basic Principle:

The capsule is injected into a high temperature (1000°C) furnace and combusted in pure oxygen under static conditions. At the end of the combustion period, a dynamic burst of oxygen is added to ensure total combustion of all inorganic and organic substances. The resulting combustion products pass through specialized reagents to produce carbon dioxide (CO2), water (H2O) and Nitrogen (N2) and oxides of nitrogen. These reagents also remove other interferences including halogens, sulfur and phosphorus. The gases are then passed over copper to scrub excess oxygen and reduce oxides of nitrogen to elemental nitrogen. After scrubbing, the gases enter a mixing volume chamber to ensure a homogeneous mixture at constant temperature and pressure. The mixture then passes through a series of high-precision thermal conductivity detectors, each containing a pair of thermal conductivity cells. Between the first two cells is a water trap. The differential signal between the cells is proportional to the water concentration, which is a function of the amount of hydrogen in the original sample. Between the next two cells is a carbon dioxide trap for measuring carbon. Finally, nitrogen is measured against a helium reference (Figure 2).

Unique Features:

With unique combination of both static and dynamic combustion, the CHN/O/S instrument can combust the widest range of sample type, from volatiles to refractories. Fully automated. Rapid analysis for high productivity - analysis time of less than 5 minutes per sample. Stable thermal conductivity detector provides linear response with superior precision and accuracy. Horizontal sample injection removes interfering residue between each sample run.

|

Location:

|

Department of Chemical Engineering, Core Lab 201D,

IIT Kanpur

|

Contact:

|

Prof. Nishith Verma

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Figure 1

|

|

Encapsulation System for Organic Photovoltaic Devices/Panels

|

Organic semiconductors are recognized as emerging materials for variety of electronic devices and displays. These have the potential of making large area photovoltaic panel on large glass sheets, metal foils and polythene sheets. This will lead to cost effective manufacturing of solar modules and panels in comparison to existing technologies. To make this happen, besides increasing the efficiency of basic devices; lifetime, durability and reliability are important aspects of this technology. Organic materials in general are much more sensitive to oxygen and moisture. The problem extenuates when current is passing through it. To overcome this problem and to test different materials for their application and ruggedness for photovoltaic applications, it is imperative that the devices and panels are encapsulated under <1ppm level of oxygen and moisture levels. To meet this end, an encapsulation system has been conceptualized, designed and installed in Semiconductor Device Lab, EE Department, IIT Kanpur. It maintains oxygen and moisture levels <0.1 ppm levels. It consists of two Glove Boxes consisting of (i) a Vacuum Oven to drive out the embedded moisture and oxygen in glass plate/foils/polythene sheets, (ii) UV ozone cleaner to clean the surface, (iii) a semiautomatic UV epoxy dispenser, (iv) platform to integrate the device/panels to covering glass plate and then (v) a UV lamp to cure the epoxy. The system has been integrated to another Evaporation cum Sputtering system for fabricating the organic devices and then ransferring the same under <0.1ppm level to Encapsulation system. It is ready for use. A photograph of the system is given below.

|

Location:

|

Department of Electrical Engineering,

IIT Kanpur

|

Contact:

|

Prof. S. Sundar Kumar Iyer

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Establishment of a CD‐Spectrometer Facility

|

Circular dichroism is the difference in the absorption of left-handed circularly polarized light (L-CPL) and right-handed circularly polarized light (R-CPL) and occurs when a molecule contains one or more chiral chromophores (light-absorbing groups). A circular dichroism signal can be positive or negative, depending on whether L-CPL is absorbed to a greater extent than R-CPL (CD signal positive) or to a lesser extent (CD signal negative). Circular dichroism = ΔA (λ) = A (λ) LCPL - A (λ) RCPL, where λ is the wavelength. Circular dichroism (CD) spectroscopy is a spectroscopic technique where the CD of molecules is measured in the visible and ultra-violet region of the electro-magnetic spectrum. CD spectroscopy is used extensively to study chiral molecules of all types and sizes, but it is in the study of large biological molecules where it finds its most important applications. A primary use is in analyzing the secondary structure or conformation of macromolecules, particularly proteins, and because secondary structure is sensitive to its environment, e.g. temperature or pH, circular dichroism can be used to observe how secondary structure changes with environmental conditions or on interaction with other molecules. Structural, kinetic and thermodynamic information about macromolecules can be derived from circular dichroism spectroscopy. This instrument has the following features:

CD spectra measurement with wavelength

Time course CD signal measurement

Facility of variable temperature(-10ºC to 110ºC) by PTC-423S/15 Peltier effect

Quartz cells with path length 10mm, 5mm, 2mm, 1mm, 0.2mm, 0.1mm

Measurement wavelength range 163 nm to 900nm.

Stray Light less than 0.0003 % (200nm).

Wavelength repeatability ±0.05nm (163 to 250 nm) and ±0.1nm (250 to 500nm), and ±0.2nm (500 to 900nm).

|

Location:

|

Core lab no. CL107E, Department of Chemistry

IIT Kanpur

|

Contact:

|

Prof. S. P. Rath

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Exhaust Emission measurement system for Internal Combustion Engines

|

The proposed emission analysis system is for measurement for (UBHC) Unburnt Hydrocarbons and (NOx) Nitrogen Oxides in engine exhaust. The “RAW Exhaust EMISSION SYSTEM” is manufactured by Horiba, Japan. The EXSA 1500 emission analysis system is a modular, innovative exhaust gas emissions analysis device that can be easily adapted to user specific requirements and can be integrated into existing test environment. The EXSA complies with latest regulatory standards for light and heavy duty test procedures such as EURO III and IV. The system is designed to fulfill the research and legislative requirements for measuring gaseous emissions. The following measurement methods are applied to the regulated emission species listed

below.

|

Emission Species

|

Method

|

|

CO

|

NDIR (Non-Dispersive Infra-Red)

|

|

CO2

|

NDIR (Non-Dispersive Infra-Red)

|

|

O2

|

PMD

|

|

NOx

|

CLD (Chemiluminescence)

|

|

THC

|

FID (Flame-Ionisation Detector)

|

|

Location:

|

Engine Research Laboratory, Department of Mechanical Engneering,

IIT Kanpur

|

Contact:

|

Prof. A. K. Agarwal

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Faro Arm

|

The Faro Arm is a counter-balanced, temperature compensated, six degree of freedom measurement arm, constructed of anodized, aircraft aluminum with precision bearings. Proprietary, hybrid analog/digital transducers at each of six joints combine to provide complete point position (XYZ) and orientation (IJK)and makes measuring complex objects easy. This includes alignment, calibration, inspection, reverse engineering and as-built documentation.

FARO Software:

-

Surfacer (Imageware)

-

AnthroCAM

|

Location:

|

CAD Lab, Department.of Mechanical Engineering,

IIT Kanpur

|

|

FTIR based Emission Measurement System for Air Pollutant Measurement

|

Procures in the Financial Year: 2011-12

FTIR Motor Exhaust Gas Analyzer MEXA-6000FT, an engine exhaust analyzer machine is capable of measuring 36 different regulated and unregulated engine emissions. Horiba MEXA-6000FT-E is an instrument for continuously measuring the concentration of the components included in engine emissions. A combination of the Fourier Transform Infra-Red spectroscopy (FTIR) and multivariate analysis enables the simultaneous concentration analysis of multiple components. This system can be used for different fuels as diesel, gasoline, Biodiesel, CNG, LPG and other alternative fuels.

|

Location:

|

Engine Research Lab, Central Workshop Complex

IIT Kanpur

|

Contact:

|

Prof. A. K. Agarwal

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

User Charges:

|

INR 2000 per sample

(Service tax is applicable for non-IITK users)

|

|

|

Fume Hood

|

A fume hood or fume cupboard is a type of local ventilation device that is designed to limit the user's exposure to hazardous or noxious fumes, vapors or dusts. A fume hood is typically a large piece of equipment enclosing five sides of a work area, the bottom of which is most commonly located at a standing work height.

|

Location:

|

NET building, Department.of Mechanical Engineering

IIT Kanpur

|

Contact:

|

Prof. Shantanu Bhattacharya

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Fused Deposition Modeling (FDM)

|

Fused deposition modeling (FDM) is a additive manufacturing technology commonly used for modeling, prototyping, and production applications.

The Technology:

The Fused Deposition Modelling (FDM) process constructs three-dimensional objects directly from 3D CAD data. A temperature-controlled head extrudes thermoplastic material layer by layer.

The FDM process starts with importing an STL file of a model into a pre-processing software. This model is oriented and mathematically sliced into horizontal layers varying from +/- 0.127 - 0.254 mm thickness. A support structure is created where needed, based on the part's position and geometry. After reviewing the path data and generating the toolpaths, the data is downloaded to the FDM machine.

The system operates in X, Y and Z axes, drawing the model one layer at a time. This process is similar to how a hot glue gun extrudes melted beads of glue. The temperature-controlled extrusion head is fed with thermoplastic modelling material that is heated to a semi-liquid state. The head extrudes and directs the material with precision in ultrathin layers onto a fixtureless base. The result of the solidified material laminating to the preceding layer is a plastic 3D model built up one strand at a time.

Once the part is completed the support columns are removed and the surface is finished.

Process:

FDM begins with a software process, developed by Stratasys, which processes an STL file (stereolithography file format) in minutes, mathematically slicing and orienting the model for the build process. If required, support structures are automatically generated. The machine dispenses two materials – one for the model and one for a disposable support structure.

The thermoplastics are liquefied and deposited by an extrusion head, which follows a tool-path defined by the CAD file. The materials are deposited in layers as fine as 0.04 mm (0.0016") thick, and the part is built from the bottom up – one layer at a time. FDM works on an "additive" principle by laying down material in layers. A plastic filament or metal wire is unwound from a coil and supplies material to an extrusion nozzle which can turn the flow on and off. The nozzle is heated to melt the material and can be moved in both horizontal and vertical directions by a numerically controlled mechanism, directly controlled by a computer-aided manufacturing (CAM) software package. The model or part is produced by extruding small beads of thermoplastic material to form layers as the material hardens immediately after extrusion from the nozzle. Stepper motors orservo motor are typically employed to move the extrusion head.

Several materials are available with different trade-offs between strength and temperature properties. As well as acrylonitrile butadiene styrene (ABS) polymer, polycarbonates, polycaprolactone, polyphenylsulfones and waxes. A "water-soluble" material can be used for making temporary supports while manufacturing is in progress, this soluble support material is quickly dissolved with specialized mechanical agitation equipment utilizing a precisely heated sodium hydroxide solution.

The term fused deposition modeling>and its abbreviation to FDM are trademarked by Stratasys Inc. The exactly equivalent term, fused filament fabrication (FFF), was coined by the members of the Rep Rap project to give a phrase that would be legally unconstrained in its use. It is a new model.

|

Location:

|

CAD Lab, Department.of Mechanical Engineering,

IIT Kanpur

|

|

|

|

|

|

Full-Band Tunable Laser TSL-210F

|

TSL-210F is a tunable laser that covers from O band to U band. Integrating optical laser units, the TSL-210F outputs power from 1260 to 1630 nm (370nm range). It can be easily controlled via GPIB with PC and software. It has excellent cost performance and shows advantages for various research and development.

Features:

370nm wide tuning range 1260 to 1630nm

Peak >10mW, 370nm>4mW (Typ.) high output power

Easy and automatic operation by exclusive software

High accuracy and stability

Built-in OTF and OVA option available

|

Location:

|

Department of Electrical Engineering,

IIT Kanpur

|

Contact:

|

Prof. Utpal Das

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Field Emission Scanning Electron Microscope

|

The unique variable pressure capabilities add an extra dimension to this FESEM. It enables ultra high resolution imaging and analysis of non conducting specimens without time consuming preparation. The true workhorse in the SUPRA™ family is well suited for failure analysis, life sciences, nanotech and analytical applications. The combination of the large analytical chamber, the new GEMINI® column and the robust VP technology delivers true performance for a wide range of applications. It features magnification power of more than one million times.

Its resolution is up to 2nm. Wide operating voltage range with minimal adjustments required, Short working distance of 8.5 mm for simultaneous high resolution imaging and X-ray analysis, High probe current (up to 20 nA) and high stability better than 0.2 %/h for analytical applications, High efficiency In-lens detector for clear topographic imaging in high vacuum mode, Enhanced VPSE detector in VP mode.

|

Location:

|

Thematic Unit of Excellence,

IIT Kanpur

|

Contact:

|

Prof. Ashutosh Sharma

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dr. Prabhat Dwivedi

This email address is being protected from spambots. You need JavaScript enabled to view it.

Dr. Dinesh Deva

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Frequency Response Analyzer

|

The Frequency Response Analyzer (FRA) is housed in the NaMPET Lab (WL‐110) for measurement and evaluation of dynamic characteristics of Power converters, sensors and electronic amplifier circuits. This instrument obtains the frequency response of the test circuit and evaluates the complex gain in polar form (magnitude and phase). The input excitation in a sinusoidal voltage, the frequency of which is swept over the range of interest and the output is converted to an equivalent voltage signal and read in by the instrument. The associated software interface allows plotting of relevant bode plots, based on this input‐output behaviour, for further analysis of its dynamic behaviour.

This equipment from Solartron Analytical (Model no. 1255B) has a frequency sweep range of 10μHz – 1MHz with a programmable excitation amplitude of 0 to 3 V rms (sensitivity 100μV), being capable of sourcing a maximum current (bipolar) of 100 mA. It has two independent analyzers in parallel allowing simultaneous test of two circuits. With a standard interface impedance of 50Ω

This equipment has been used for determining the actual dynamic behaviour of a physical circuit and the test results are used for either validating or improving the analytical dynamic model of a system or to derive one, in black‐box situations. The test results shown are for a motor drive for aerospace applications, used by the Aerospace Engineering Department. This instrument has also been used to determine the cut‐off frequencies of sensor circuits used for online voltage feedback in power applications.

|

Location:

|

NaMPET Lab, Department of Electrical Engineering,

IIT Kanpur

|

Contact:

|

Prof. Parthasarathi Sensarma

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Frequency Response Analyzer

|

The Frequency Response Analyzer (FRA) is housed in the NaMPET Lab (WL‐110) for measurement and evaluation of dynamic characteristics of Power converters, sensors and electronic amplifier circuits. This instrument obtains the frequency response of the test circuit and evaluates the complex gain in polar form (magnitude and phase). The input excitation in a sinusoidal voltage, the frequency of which is swept over the range of interest and the output is converted to an equivalent voltage signal and read in by the instrument. The associated software interface allows plotting of relevant bode plots, based on this input‐output behaviour, for further analysis of its dynamic behaviour.

This equipment from Solartron Analytical (Model no. 1255B) has a frequency sweep range of 10μHz – 1MHz with a programmable excitation amplitude of 0 to 3 V rms (sensitivity 100μV), being capable of sourcing a maximum current (bipolar) of 100 mA. It has two independent analyzers in parallel allowing simultaneous test of two circuits. With a standard interface impedance of 50Ω

This equipment has been used for determining the actual dynamic behaviour of a physical circuit and the test results are used for either validating or improving the analytical dynamic model of a system or to derive one, in black‐box situations. The test results shown are for a motor drive for aerospace applications, used by the Aerospace Engineering Department. This instrument has also been used to determine the cut‐off frequencies of sensor circuits used for online voltage feedback in power applications.

|

Location:

|

NaMPET Lab, Department of Electrical Engineering,

IIT Kanpur

|

Contact:

|

Prof. Parthasarathi Sensarma

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Gas chromatography-mass spectrometry (GC-MS)

|

Gas chromatography-mass spectrometry (GC-MS) is a method that combines the features of gas-liquid chromatography and mass spectrometry to identify different substances within a test sample. Applications of GC-MS include drug detection, environmental analysis, explosives investigation, and identification of unknown volatile samples. Additionally, it can identify trace elements in materials that were previously thought to have disintegrated beyond identification. The GC-MS is composed of two major building blocks: the gas chromatograph and the mass spectrometer. The gas chromatograph utilizes a capillary column which depends on the column's dimensions (length, diameter, film thickness) as well as the phase properties (e.g. 5% phenyl polysiloxane). The difference in the chemical properties between different molecules in a mixture will separate the molecules as the sample travels the length of the column. The molecules take different amounts of time (called the retention time) to come out of (elute from) the gas chromatograph, and this allows the mass spectrometer downstream to capture, ionize, accelerate, deflect, and detect the ionized molecules separately. The mass spectrometer does this by breaking each molecule into ionized fragments and detecting these fragments using their mass to charge ratio. The most common type of mass spectrometer (MS) associated with a gas chromatograph (GC) is the quadrupole mass spectrometer, sometimes referred to by the Hewlett-Packard (now Agilent) trade name "Mass Selective Detector" (MSD). Another relatively common detector is the ion trap mass spectrometer. The GC-MS assembly is manufactured and marketed by many companied like Agilent, Shimadzu, Perkin Elmer, Thermo Fischer. An Agilent GC-MS was purchased in IIT-Kanpur under the project CARE-2007. The main features of the instrument are as follows,

-

The GC has MSD interface and can be run in split or splitless mode. It has a three way splitter which enables the simultaneous detection by three detectors for analysis, i.e Micro ECD, NPD with EPC and MS.

-

Auto injector with 8 vials capacity.

-

Columns: DB-5/HP-5, DB-Wax, DB-1701, DB-35MS.

-

NIST and Wiley library.

|

Location:

|

Core lab, 203-E, Department of Chemistry,

IIT- Kanpur.

|

Contact:

|

Prof. R. Gurunath.

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Gravity Convection Oven

|

A special gas or electric oven equipped with a fan that provides continuous circulation of hot air around the sample to be heated.

|

Location:

|

NET building, Department.of Mechanical Engineering

IIT Kanpur

|

Contact:

|

Prof. Shantanu Bhattacharya

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Geared Stirrer (Remi-rqg-128 a/d)

|

The Remi geared stirrer is especially applicable for stirring fluids at a constant rate with a maximum capacity of 8 lts.

It has an 8mm diameter and 450mm long stirring shaft. It gives a speed ranging from 50 to 550 rpm. This is an in-house facility and cannot be borrowed out of the Lab. Use On Payment basis - for details see Forms in http://www.iitk.ac.in/ibc/

|

Location:

|

Ion Beam Complex, NL-105, Department of Physics, IIT Kanpur.

|

Contact:

|

Co-ordinator, IBCOR

Mr. S. Krishnasamy

Technical Superintendent, IBC

(

This email address is being protected from spambots. You need JavaScript enabled to view it.

).

Phone: 7986 / 6993

|

|

HIGH POWER RF AMPLIFIERS FACILITY

|

The High Power RF Amplifiers (Model 100A250A) facility is present in Microwave Circuit Laboratory at Department of Electrical Engineering IIT Kanpur. The High Power RF Amplifiers 100A250A Amplifier is a self contained, broadband amplifier designed for laboratory applications where instantaneous bandwidth, high gain and moderate power output are required. Utilization of push-pull MOSFET circuitry lowers distortion, improves stability and allows operation into any load impedance without damage. The AR 100A250A Amplifier, when used with an RF sweep generator, will provide a maximum of 100 watts of swept power.

Specifications & Features:

Rated Output Power: 100 watts, Power Output @ 3dB compression (Nominal: 157 watts), Power Output @ 1dB compression (Nominal: 107 watts), Flatness: ± 1.5 dB maximum, Frequency Response: 10 kHz - 250 MHz instantaneously, Gain (at maximum setting): 50 dB minimum, Gain Adjustment (continuous range): 18 dB minimum, Input Impedance: 50 ohms, VSWR 1.5:1 maximum, Output Impedance: 50 ohms, VSWR 2.0:1 maximum. Modulation Capability: Will faithfully reproduce AM, FM, or pulse modulation appearing on the input signal, Remote Interfaces: IEEE-488, RS-232, RF Input: Type “N” female on front panel, RF Output: Type “N” female on front panel.

|

Location:

|

Microwave Circuit Laboratory, Department of Electrical Engineering,

IIT Kanpur

|

Contact:

|

Prof. Kumar Vaibhav Srivastava

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

High Temperature Electrochemical Test Station

|

This Instrument is specially designed for testing proton exchange membrane (PEM) fuel cells, and solid oxide fuel cell (SOFC) using the Probostat fixture with maximum temperatures of 800°C. The test stations can be used for characterization of components, the evaluation of SOFC single cells and for optimization of processes. This system is ideal for researchers and developers to begin or expand their testing of Solid Oxide Fuel Cell button cells.

Unique features:

The Test Station provides control of flow (MKS Type 1179A and 2179A Mass-Flo Controller and Type 179A mass-Flo Meter), heating rate, humidity, back-pressure (Maximum 70 psig), temperature (Type T thermocouple) and pressure for the anode and cathode gases. The station incorporates a DC electronic load. The Station also includes two humidity bottles.

-

This station tests single cells and any stack of up to 10 Volts and 100 amps at 150watts maximum power. An electronic load that is programmable through a GPIB/PC interface controls the voltage and current.

-

Safety features include an anode nitrogen purge, an automatic system shutdown of anode and cathode gas streams, humidity bottles and cell heaters.

-

The ProboStat is a cell for measurement of electrical properties, transport parameters etc. It is also used to find the kinetics of materials, solid/gas interfaces and electrodes under controlled atmospheres at high temperatures.

-

The furnace is 3210 Series Split Tube Furnace with dimensions 3-3/4 in. ID x 12 in. OD x 9 in. long. The heating length is 6 in. The material used in manufacturing is Kanthal A1 and the maximum achievable temperature is 1100OC. Power Input required is 230V AC supply.

|

Location:

|

WL210, Department of Materials Science & Engineering,

IIT Kanpur

|

Contact:

|

Prof. Krishanu Biswas

kbiswas@ iitk.ac.in

|

|

High-performance liquid chromatography

|

High-performance liquid chromatography (or high-pressure liquid chromatography, HPLC) is a chromatographic technique that can separate a mixture of compounds and is used to identify, quantify and purify the individual components of the mixture. The HPCL (Varian) (Figure 1) was established in the Environmental Lab in 2010 with the DST grant of the Institute.

Basic Principle:

Separation is based on the analyte’s relative solubility between two liquid phases. HPLC utilizes different types of stationary phase (typically, hydrophobic saturated carbon chains), a pump that moves the mobile phase(s) and analyte through the column, and a detector that provides a characteristic retention time for the analyte. Analyte retention time varies depending on the temperature of the column, the ratio/composition of solvent(s) used, and the flow rate of the mobile phase. With HPLC, a pump (rather than gravity) provides the higher pressure required to propel the mobile phase and analyte through the densely packed column (Figure 2). HPLC – Modes: Normal Phase - Polar stationary phase and non-polar solvent and Reverse Phase - Non-polar stationary phase and a polar solvent.

Unique Features:

Fully integrated, fully automated, modular HPLC pumping systems. With a wide range of flow rates, precise solvent flow and system pressure are maintained with a built-in pressure unit. User-friendly pump heads are self-contained units that can be rapidly exchanged by simply loosening a finger-tight clamp. PEEK and titanium pump heads are available to protect biological samples from trace amounts of metal ions that might be released from components in the fluid path.

|

Location:

|

Department of Chemical Engineering, Environmental Lab,

IIT Kanpur

|

Contact:

|

Prof. Nishith Verma

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

Figure 1

|

Figure 2

|

Figure 3

|

|

HIGH RESOLUTION ESI-MS (LC-MS) FACILITY

|

Electrospray ionization is a technique used in mass spectrometry to overcome the propensity of macromolecules to fragment (Nobel Prize in Chemistry, 2002).

In ESI, a liquid containing the analyte is pushed through a very small charged metal capillary by a carrier gas. The charge contained in the capillary is transferred to the liquid, which charges the g g p y q , g analyte molecule. As like charges repel, the liquid pushes itself out of the capillary and forms an aerosol of small droplets. A neutral carrier gas is used to evaporate the neutral solvent in the small droplets, this in turn brings the charged analyte molecules closer together. As proximity of the molecules in the droplet becomes lesser and similarly charges molecules come closer together, the droplets explode. This process repeats itself until the analyte is free of solvent and is reduced to lone ions. The lone ions will then continue along to a mass analyzer.

Capability:

ESCI ionisation capability that allows both ESI and APCI to be performed, during one experiment, with the same source.

|

Location:

|

Department of Chemistry

IIT Kanpur

|

Contact:

|

Prof. S. N. Tripathi

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Hot Isostatic Press

|

Hot Isostatic Pressing (HIP) process, subjects a component to elevated temperatures and pressures eliminates internal voids and creates clean, firm bonds and fine, uniform microstructures. The virtual elimination of internal voids helps in designing components to near-net shapes of improved fatigue strength. Generally HIP process enables to produce materials of all shapes and sizes, including cylindrical billets, flat rectangular bar billets, solid shapes with complex external geometry, and complex shapes with internal cavities HIP process provides a method for producing components from diverse powdered materials, including metals and ceramics. During the manufacturing process, a powder mixture of several elements is placed in a container. The container is subjected to elevated temperature and very high vacuum to remove air and moisture from the powder. The container is then sealed and HIP’ed. The application of high inert gas pressures and elevated temperatures results in the removal of internal voids and creates a strong metallurgical bond throughout the material. The result is a clean homogeneous material with a uniformly fine grain size and a near 100% density.

Technical Specification:

Max Pressure: 30,000 psi

Max Temperature: 2200 0C

Environment: Argon gas

Die material: Graphite

|

Location:

|

ACME building, 208

IIT Kanpur

|

Contact:

|

Prof. J.Ramkumar

This email address is being protected from spambots. You need JavaScript enabled to view it.

Prof. Kamal. K. Kar

This email address is being protected from spambots. You need JavaScript enabled to view it.

|

|

Hot Plate (Tarsons- 231b-5040)

|

The Tarsons Hot plate has a 18cmx18cm ceramic top for placing the samples on I for heating. Even beakers can be heated on it.

The temperature can be varied from 100℃ to 1000℃. This is an in-house facility and cannot be borrowed out of the Lab. Use On Payment basis - for details see Forms in http://www.iitk.ac.in/ibc/

|

Location:

|

Ion Beam Complex, NL-105, Department of Physics, IIT Kanpur.

|

Contact:

|

Co-ordinator, IBC

OR

Mr. S. Krishnasamy

Technical Superintendent, IBC

(

This email address is being protected from spambots. You need JavaScript enabled to view it.

).

Phone: 7986 / 6993

|

|

iCAP 6300 ICP Spectrometer

|

The use of Inductively Coupled Plasma source (ICP) and Atomic Absorption (AA) are the accepted and most powerful techniques for the analysis of and quantification of trace elements in both solid and liquid samples. Applications range from routine environmental analyses to the materials industry, geological applications to clinical research and from the food industry to the semiconductor industry. The iCAP 6300-Duo can simultaneously detect 66 Elements with detection limits less than 1μg/L. The plasma is easier to ignite and can operate with a much wider range of sample types. The Duo instrument provides flexibility, with extreme detection limits achievable in axial mode and reduced interference in Radial mode.

|

Technical Specification

|

|

|

Spectrometer

|

Echelle type

|

| |

52.91 grooves/mm ruled grating

|

| |

383 mm effective focal length

|

| |

9.5 0UV fused silica cross dispersion prism

|

|

Wavelength range

|

166 – 847 nm

|

|

Spectral bandpass

|