The experimental facilities available in the laboratory are grouped into the following categories:

The following experimental facilities are available:

It is an electronics equipment with trigger control-digital display. It is used for measuring the spot speed of a vehicle.

Video recording unit helps in continuous field data acquisition.

GNSS receiver determines the user position, velocity, and time by processing the signals broadcasted by satellites.

An instrumented vehicle is a vehicle equipped with a variety of instruments such as distance measuring sensor, speed measuring sensor, etc. and this vehicle runs along with the traffic stream collecting traffic data either actively or passively.

Lidar is a remote sensing method that uses pulsed laser to measure ranges (variable distances) to the Earth.

The IMU-GPS combines micro inertial sensors and an embedded Global Positioning System (GPS) receiver which can provide the vehicle position.

The steering angle sensor can provide the steering wheel angle.

The brake pedal sensor is used for data collection on brake application (by sensing the pressure applied to brake).

The accelerator pedal sensor is used for data collection on acceleration.

The GSFS measures the force applied during gear change.

The following experimental facilities are available:

Analog Marshall test apparatus

Digital Marshall test apparatus

Marshall apparatus is used to measure the resistance of cylindrical bituminous mix specimens to plastic flow under loading on the lateral surface. This test method is used for bituminous mix design.

The following experimental facilities are available:

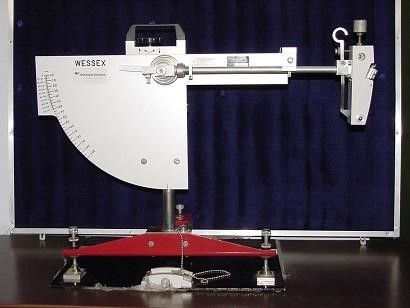

Static creep pavement deflection is measured by the Benkelmen Beam (BB). The overlay thickness required for strengthening of a given road stretch can be estimated from the BB deflection record and other necessary design parameters.

This equipment is used for checking and recording the smoothness of profiles of pavements. The equipment, developed by Central Road Research Institute, New Delhi (CRRI), comprises of a mobile trussed frame, four datum wheels which provide the plan of reference with respect to which the instrument, moves along the pavement surface during the test. The probing wheel undulates with the surface irregularities and the pen marker linked to probing wheel records the magnitude of the undulation on a graph sheet. The road roughness level is estimated using this equipment.

This equipment is used for measurement of skid resistance on field and laboratory samples.

It is used for measuring the deflection and modulus of subgrade/subsoils and unbound base layers.

The following experimental facilities are available:

The amount of water present in a material is expressed as a percentage by mass of the material. For water content test of bitumen “Dean and Stark” method is used.

It is a process in which a semisolid, liquid, vapor or mixture of two or more substances is separated into its component fractions by the application or removal of heat.

In this method the maximum possible elongation of bitumen, placed in a standard briquette, is measured under specific test conditions.

This is an open-cup apparatus for determination of flash and fire point of bituminous binders using Pensky-Martens Method.

The consistency of bituminous binder at an elevated temperature is determined by float test.

The objective of this experiment is to determine the consistency of bitumen for classifying bitumen samples into different grades.

Softening point test measures the temperature at which bitumen attains a particular degree of softening.

In this test, the loss of weight of bitumen is studied while the sample is kept at constant temperature.

Rotational viscometer

Tar viscometer

The rotational viscometer is used to measure the viscosity of bitumen at a given temperature.

Tar viscometer provides a surrogate measure of viscosity (applicable to low viscosity binders).

Capillary viscometer

The capillary viscometer measures the kinematic viscosity The equipment can work within the temperature range of 20 to 100°C.

Flakiness and elongation index text gauges

Aggregate impact value gives the relative strength of aggregates against impact loading.

Additionally, facilities are available to perform alkali-aggregate reaction test, sand equivalent test and soundness test on aggregates.

This equipment simulates the polishing of stone aggregates that happen in in-service pavement. The change in skid resistance is then measured in British Pendulum Tester.

It performs real-time monitoring and dynamic analysis of chemical, physical and biological processes. Over a period of hours or days, it determines the onset, rate, extent and energetics of such processes for specimens in small ampoules at a constant set temperature.

It measures both heat flow and weight changes in a material as a function of temperature or time in a controlled atmosphere.

The film-stripping test is used to measure the resistance of bituminous mixture to stripping of bitumen from aggregates.

The equipment is used for the quantitative determination of bitumen in bituminous mix.

Used for studying fatigue performance of bound pavement materials.

This equipment estimates bitumen content in bituminous mix by complete burning.

Tests can be performed in static and dynamic (of various frequencies and waveforms) to capture the response on asphalt mix and granular materials.

The following experimental facilities are available:

Vacuum oven

Vacuum pump