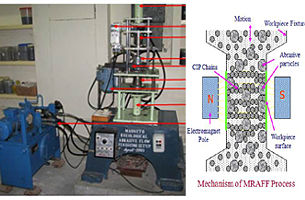

In this area, various nano-finishing processes and strategies like Magentorhelogical Abrasive flow finishing (MRAFF) is utilized to develop surface finishes less than 100nm which are heavily utilized for prosthetics, implants, nuclear reactors, micro-mirrors etc. The magnetorheological fluids demonstrate change in apparent viscosity under external magnetic fields. In this process, a viscous slurry made of Carbonyl Iron Particle and the abrasive grains are passed through external magnetic fields resulting in their local increase in viscosity. This leads to positive pressure of the abrasive particles on the metal pipe interiors through which the slurry is passed.

Research Areas

Micromachining of channels using ECDM processes, nanofinishing using MRAFF, and MAF processes

Research Laboratories:

Manufacturing Science Laboratory

Associated Faculty

V. K. Jain, PhD (Roorkee): Advanced Machining Processes, Accelerated Cutting, CAM Machining of Advanced Engineering Materials

|

|

Magnetorheological Abrasive Flow Finishing (MRAFF) Process

|

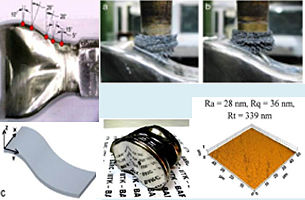

Nanofinishing of knee joint implant (Ti alloy) by MRF

|