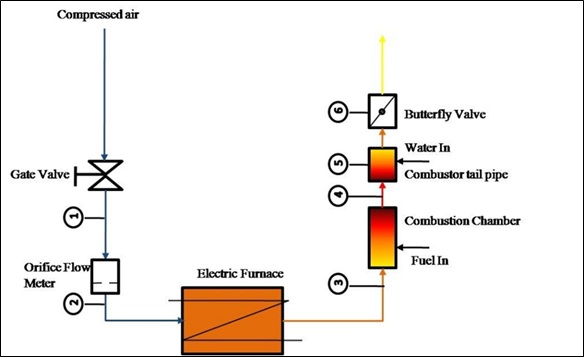

This facility was developed to supply high pressure, high temperature air for experiments. It is supplied by a diesel engine powered air-screw type compressor capable of delivering a maximum mass flow rate of 0.5 kg/s at 20 bar gauge pressure. The air flow and pressure are regulated using a gate valve at the inlet of the facility. An orifice flow meter is used to measure the mass flow rate through the facility. A 200 KW electric furnace consists of many heating elements placed around the pipe carrying air. The section of the pipe within the furnace is filled with ceramic balls, which absorb heat from the heating elements and transfer it to the air passing over them. The test section is modular, depending on the component that needs to be tested.

Specifications:

Maximum mass flow rate: 0.5 kg/s

Maximum delivery pressure: 20 bar gauge

Furnace Power: 200 kW

Delivery Temperature: ambient to 900 oC

Flow pipe diameter: 101.6 mm

Completed Research

Applications of Bio-Fuels for Aviation: A can type combustor was attached to the high enthalpy rig for testing with bio-fuels. The combustor was tested at different operating conditions, simulating the real engine operating conditions. Pressure, temperature and emission measurements were made for all the different bio-fuels and test conditions.

Related Publications

Ramraj H. Sundararaj, Anoop Raut, A. Nageshwara Rao and A. Kushari, “Uneven Combustion Leading to Catastrophic Failure in Gas Turbine Combustor”, NPC2015-101, National Propulsion Conference, 23-24 Feb. 2015, IIT Mumbai, Mumbai, India.

Future Research

Suppression of Infra-red signature from Nozzle Exhaust