Our Facilities

Additive Manufacturing Lab (AM Lab)

Additive manufacturing, sometimes called 3D printing, is a process used to build geometry out of a raw material without the constraints of traditional tooling. Generally, software is used to "slice" a 3D model into thin layers which are built successively onto a build platform. Multiple additive technologies exist, each with the ability to produce a variety of materials and geometries. Each machine and material has unique properties that should be considered when choosing a process.

Do you need a 3D part printed, but don't have access to a 3D printer or don't want to wait for a 3D printer in the lab to become available? Try the MedTech IITK 3D Printing Service.

Prototyping Service includes:

| Maker | Machine | Image | Technology | Software | Layer Resolution | Build volume (xyz) | Material | Best option for: |

|---|---|---|---|---|---|---|---|---|

| Markforged | Metal X |  |

ADAM (Atomic Diffusion Additive Manufacturing) | GrabCAD Print | 0.005", 0.007", 0.010", 0.013" | 300 x 220 x 180 mm | Inconel 625, (D2,H13,A2) Tool Steel, 17-4 PH Stainless Steel, H13 Tool Steel, A2 Tool Steel, Copper | High reliability, structural parts.Best option for metal 3D prints |

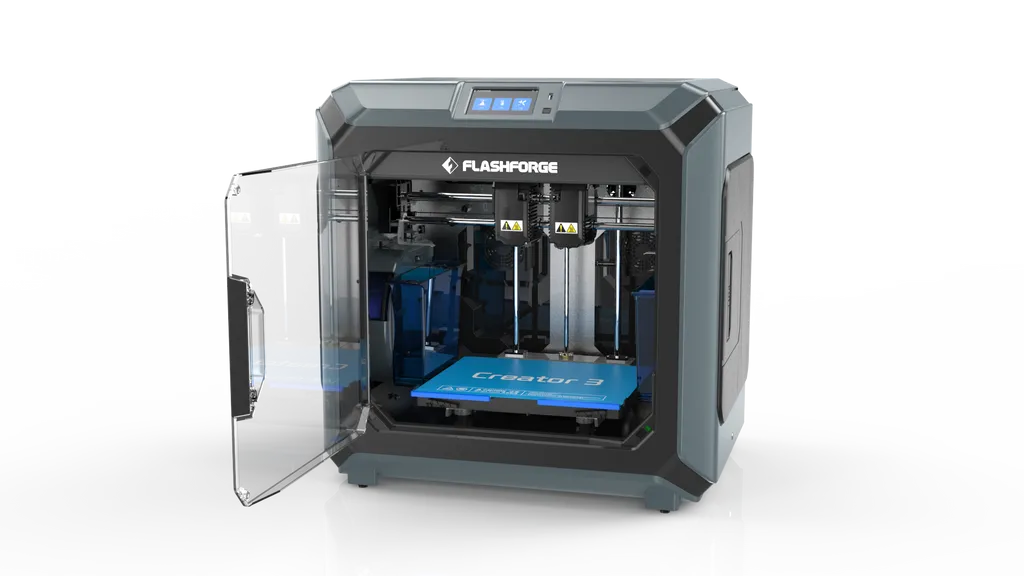

| Flashforge | Creator 3 |  |

FFF (Fused Filament Fabrication) | Cura | 0.06mm - 0.25mm | 300 x 250 x 200 mm | ABS, ASA, PC-ABS, PLA, TPU92A soluble support material | Inexpensive or experimental prints |

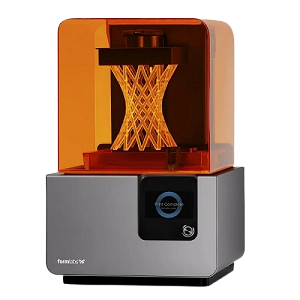

| Formlabs | Form2 |  |

SLA LFS (Low Force SLA) | PreForm | 25um, 50um, 100um, 140um, 300um | 125mm x 125mm x 160mm | Most Formlabs resins are stocked | Small, precise parts with intricate features.When a specific resin's material properties are required. |

| Sintratec | S1 |  |

SLS (Selective Laser Sintering) | Sintratec AG | 25um, 50um, 100um, 140um | 130 x 130 x 180 mm | Currently Nylon PA12 is stocked | customize a lot of parameter to work with individual materials and density properties of the sintering speed. |

Fab Lab/Electronics

Introduction to electronic lab components or equipment's. Basic purpose of this electronic lab components article is to introduce you with electronics lab components and their use in electronics lab experiments. In electronic circuit lab, the primary piece of equipment that you will be dealing with is the Trainer Board. A trainer board is essentially a collection of most of the electronic lab components that are typically required when working with logic circuits

Wet Lab

A wet lab, or experimental lab, is a type of laboratory where it is necessary to handle various types of chemicals and potential "wet" hazards, so the room has to be carefully designed, constructed, and controlled to avoid spillage and contamination.

POST PROCESSING

Bead Blasting Station

Bead blasting is a finishing technique for 3D-printed parts. It's an abrasive blasting method, which means that it is similar to sandblasting and water blasting (pressure washing). In bead blasting, fine beads of plastic, glass, or another substance are forcibly sprayed over the surface of a part. The type of beads are chosen depending on the part's material in order to smooth the finish of the part without damaging it. Bead blasting creates a uniform matte finish over the surface of the part. Most customers consider this the standard finish - build markings are smoothed out, but additional high quality finishing has not been applied. It's ideal for assessing a prototype, or for finishing a piece that doesn't need a "show ready" finish. Bead blasting also makes it easier to photograph parts because it reduces the light reflections from the part's surface. For pieces that will be used for sales meetings and trade shows, most customers prefer a higher quality finish.

Vapour Smoothing

Vapor Smoothing is a fast, effective way to achieve a smooth finish for your 3D Printed Objects. By using the ULTRA Vapor Smoothing System, 3D printed parts can be finished to a fine smoothness without losing the detail of the original printed part.

Metal powder coat on 3d Print

Metal powder coating over polymer 3d prints provides greater impact/scratch resistance and prevent the parts from weather conditions. This technology can also be used to enhanced the aesthetic appealed.