|

|||||||||||||||||||||||||||||||||||||||||||||||

|

The TA Q600 provides a true simultaneous measurement of weight change (TGA) and true differential heat flow (DSC) on the same sample from ambient to 1,500 °C. It features a field- proven horizontal dual beam design with automatic beam growth compensation, and the ability to analyze two TGA samples simultaneously. DSC heat flow data is dynamically normalized using the instantaneous sample weight at any given temperature.

Technical Specification:

|

|

||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

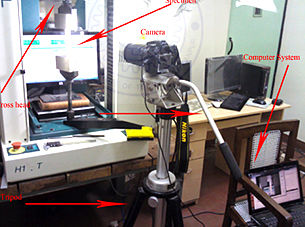

TINIUS OLSEN H10KTThe TINIUS OLSEN H10KT is a dual column Universal Testing Machine having a frame capacity of 10kN. This machine is designed to test a wide range of materials, including, but not limited to: metals, laminated composites, rigid plastics, films, paper, thin sheet metal, adhesives and foils, in tension, compression, flexure, shear, and peel. This machine has an environmental chamber which has been designed to operate over a temperature range of ambient up to 300˚C employing electrical heating elements thus allowing the samples to be heated and tested at a higher temperature. Load measurement accuracy: +/- 0.5% of indicated load from 2% to 100% capacity; extended range. Position measurement accuracy: +/- 0.01% of reading or 0.001 mm, whichever is greater. Speed accuracy: +/- 0.005% of set speed.

Technical Specification:

INSTRON - 3345The INSTRON -3345 Single Column Systems are ideal for tension and/or compression applications where tests are less than 5 kN (1,100 lbf), lab space is limited, and where free access to the test area is desirable. The 3340 Series Single Column Testing Systems provide simplicity, performance, and affordability for quality control (QC) labs and production testing.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Maximum Load |

5KN |

Vertical test space |

1123mm |

|

Maximum Speed |

1000mm/min |

Total cross head travel |

885mm |

|

Minimum speed |

0.05mm/min |

Column spacing |

100mm |

|

Maximum speed at Maximum load |

1000mm/min |

Total Height |

1358mm |

|

Maximum load at maximum speed |

5KN |

Total Weight |

382mm |

|

Cross head return speed |

1000mm/min |

Total depth |

500mm |

|

Weight |

52Kg |

Maximum power |

300VA |

|

Software model |

Bluehill lite |

|

|

|

||||||

|

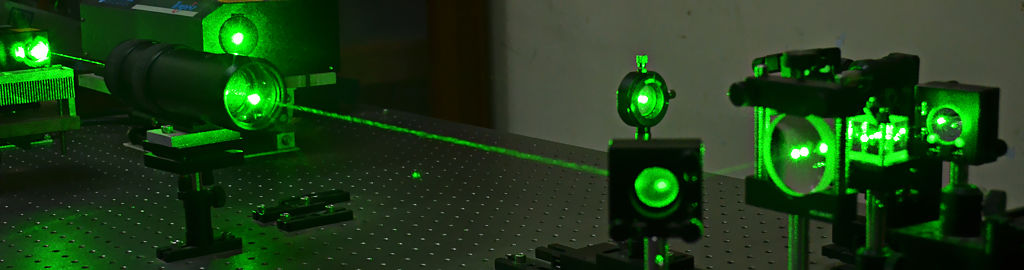

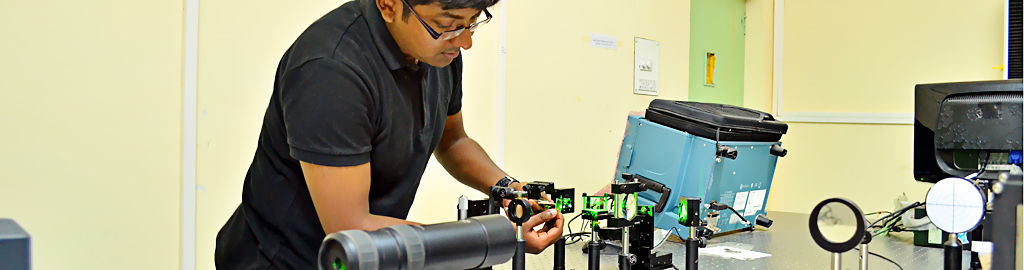

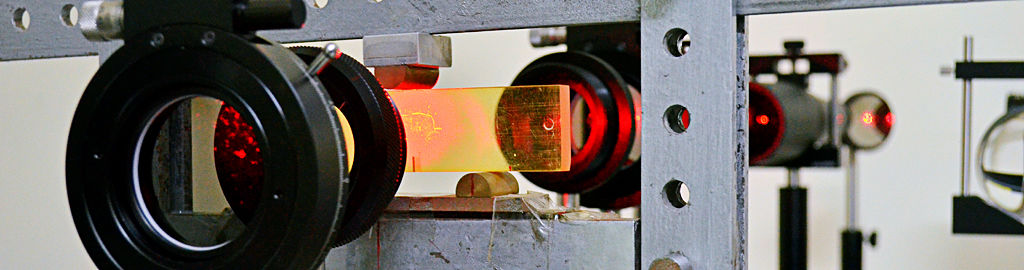

Digital Image Correlation (DIC), is an optical non contact method, used to acquire displacements by tracking a unique distribution of pixel intensities of a grey scale image called a pattern or template. These patterns are correlated over a series of camera obtained

Images of the object in concern to give the pixel displacement of the surface in two dimensional images which can be interpreted according to the three dimensional motion. This method is highly utilised when the object is too light, too small, having variation in temperature or working at high speeds, which prevents the use of traditional contact methods. 2D (for In plane deformation) & 3D DIC (for out of plane deformation) are commonly used in structural dynamic testing and in experimental mechanics specially fracture. Two or more cameras of high specification and resolution are employed in stereo-vision system principle in order to acquire 3D location of the points while single camera is employed for in plane testing.

DIC Cameras

The Stereo Vision DIC requires images obtained by both cameras simultaneously. High speed cameras are preferable for accurate measurement. Olympus i-speed TR cameras are being used in the experiment which has the ability to synchronise both the cameras at a time using a trigger.

|

|

|||||

|

||||||

|

Prepreg Manufacturing Machine: A prepreg manufacturing machine, designed at aerospace engineering, IIT Kanpur

Technical Specification: Length of the drum= 2 feet 85 inches. It has an oil bath circulator for heating the epoxy resin mixture , double walled, inner made of thick gauge

|

|

|||||