Welcome Message

Welcome to the Department of Mechanical Engineering at IIT Kanpur. We started our journey in the year of 1960. Over the last six decades, we have grown our expertise and competence in the core Mechanical Engineering curriculum and research....

- Read More

-Prof. Ashish Dutta

Head, Department of Mechanical Engineering

Featured Faculty

Admission to both B. Tech. and B. Tech. - M. Tech. dual degree programs is made once a year in July through a Joint Entrance Examination (JEE) conducted on an All India level in April/May. The minimum academic qualification for appearing in JEE is a pass in the final examination of 10+2 system or its equivalent. One should not be more than 25 years of age (30 years for SC/ST) as on 1st October after admission. Admission is offered on the basis of one's choice vis-a-vis his/her All India Rank in the JEE. Requests for application forms should be sent to the Chairman, Joint Entrance Examination, IIT-Kanpur. For the detailed procedure in this regard, write to Chairman JEE, IIT Kanpur - 208016, INDIA before the end of December preceding the year in which admission is sought.

A student can get admission in the undergraduate degree programs (B. Tech. and B. Tech. - M. Tech. dual degree) of Mechanical Engineering through the following ways:

- Through Joint Entrance Examination -Admissions to the Bachelor of Technology are made once a year in July through Joint Entrance Examination (JEE) conducted on an All India level by IITs. The procedures and other requirements for admission are specified in the JEE Information Brochure brought out every year.

- A few admissions are offered under the Cultural Exchange Fellowship Program of the Government of India, administered by Indian Council of Cultural Relations (ICCR), New Delhi. For these fellowships, the candidates are required to apply through the Indian High Commission/Embassy in their respective countries.

- Reservations of Seats and Admission for reserved seats - Reservation of seats for the various categories shall be as prescribed by the Board of governors. The admission process for the reserved seats is as stated below:

- SC and ST Candidates-Reserved seats are filled on the basis of JEE qualifying norms specified for them. In case these reserved seats remain vacant, other SC and ST candidates (who appeared in JEE and satisfy certain relaxed conditions) are offered admission to the Preparatory Course of one year duration in Physics, Chemistry, Mathematics and English. On completion of the preparatory course and passing of the examination conducted by the Institute, the candidates are offered admission to the first year of B. Tech. program against the vacant reserved seats of the year of their appearance in JEE.

- Other Backward Classes (OBC) Candidates (Not belonging to creamy layer)- Reserved seats are filled on the basis of JEE qualifying norms specified for them.

- PD Candidates-Reserved seats are filled on the basis of JEE qualifying norms specified for them. In case these reserved seats remain vacant, other candidates in their respective categories are offered admission.

- Admission with Advanced Standing -Normally, admissions are made to the first year of the B. Tech. programmes. However, under exceptional circumstances, the Senate may admit a student with advanced standing (up to a maximum of four semesters) on the basis of his/her partial completion of a similar programme elsewhere.

- Change of Programme -The students shall normally pursue the respective B. Tech. programmes allocated to them at the time of admission. However, the Senate may permit a limited number of students to change their programme as per the approved guidelines.

Our Student Outcomes describe what students are expected to know or be able to do by the time of graduation from our program.

Some of the notable outcomes are:

- an ability to apply the acquired knowledge of mathematics, science and engineering.

- an ability to design and conduct an experiments, and interpret the results by analyzing.

- an ability to design a system, component, or process to meet the desired needs within certain realistic constraints such as economic, environmental, social, safety, manufacturability, and sustainability.

- an ability to use the techniques, skills, and modern engineering tools necessary for engineering practice.

- an ability to identify, formulate, and solve engineering problem.

- an ability to function in a multidisciplinary teams.

- an understanding of contemporary issues related to engineering and an ability to engage in life-long learning.

- an ability to communicate effectively.

- an understanding of professional and ethical responsibility.

The Bachelor of Technology (B. Tech.) program in Mechanical Engineering has a strong flavor on design and hands-on experience. The program includes a deeper study of a number of engineering sciences to which students are introduced at the core curriculum level, theoretical and experimental solution of physical problems, and design of systems relevant to the contemporary industries. The areas introduced by the department include Energy Conversion and Power Systems, Heat Transfer and Fluid Mechanics, Mechanics of Solids, Manufacturing Science, Industrial Engineering, Automatic Controls and Engineering Design and Optimization. Besides the theoretical and laboratory based curriculum, students complete an advanced design project in the final year of the program.

This degree provides a solid foundation in core mechanical engineering disciplines, critical thinking and problem-solving skills. Through the academic program students also develop excellent written and oral communication skills, learn to work as a team and project management.

The objectives of this undergraduate program are:

- To provide the highest level of education in technology and science and to produce competent, creative and imaginative engineers.

- To promote a spirit of free and objective enquiry in different fields of knowledge.

- To make a significant contribution towards the development of skilled technical manpower To create an intellectual reservoir to meet the growing demands of the nation.

- The undergraduate programs are designed to achieve these objectives and to inculcate in the student concepts and intellectual skills, courage and integrity, awareness of and sensitivity to the needs and aspirations of the society.

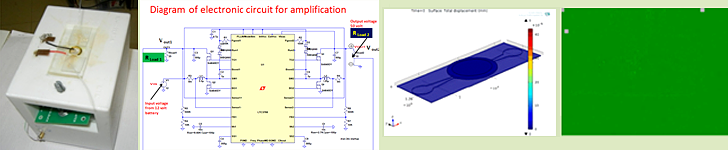

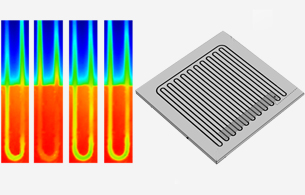

Piezo-based micro pump

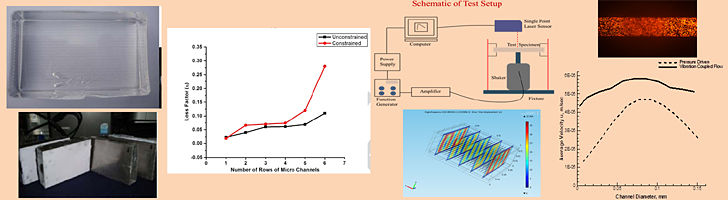

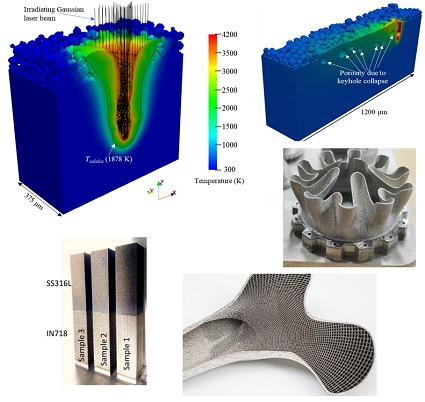

Research is focused on the following key areas: manufacturing systems, manufacturing processes, additive manufacturing, welding, casting, advanced machining processes, micro/nano fabrication and finishing, nanotechnology, bioengineering, nano-composites, MEMS, laser/plasma surface coating, large deformation systems, CAM of advanced engineering materials, polymer processing and rheology, lab on chip, vibration control of machine tools, adaptive control system, unconventional machining, solid-liquid phase change (melting/solidification).

Participating Faculty

Research Laboratories

| Manufacturing Lab |

|

| Micro systems Fabrication Laboratory | Wire Bonder, Desk Top Mask Aligner, DI water system, Chemical Balance, Fume Hood, Gravity Convection Oven, Optical Table, Spin Coater, Air cooled Chiller, Sputtering / PECVD Dual System, Oxidation Furnace, Dicing Saw |

| Solidification Laboratory | In-situ PIV, PLIF and HR imaging facility for melting/solidfication, In-situ experimental and HR imaging facility for droplet impact on surfaces, Laser welding, Experimental facility for PCM based thermal storage, Opensource software for additive manufacturing, welding, casting, thermal spray coating, thermal storage. |

| Additive Manufacturing Facility | Laser powder bed fusion based metal 3D printing equipment |

| Computational Manufacturing Systems Laboratory | Individual desktop workstations |

| Advanced Nano-engineering Materials Laboratory | AFM, SEM, Raman, DSC, TGA, DMA, UTM, PECVD, etc |

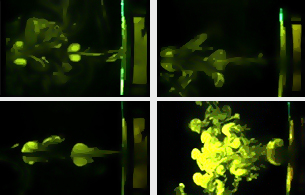

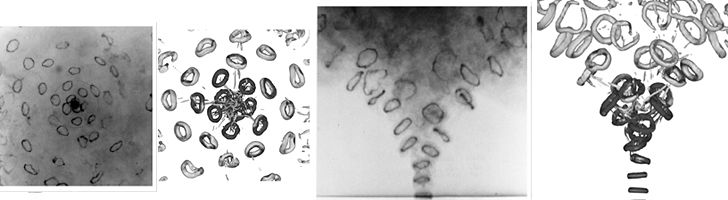

Experimental and Numerical Studies of Blooming Jet

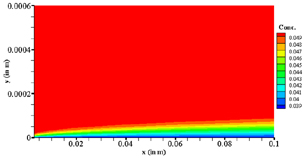

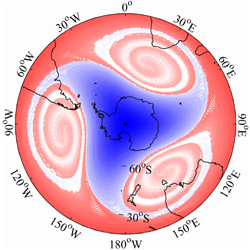

Researchers in the Transport Phenomena and Multi-Physics Simulations track work in the areas of theoretical, experimental and numerical methods for fluid flow and heat transfer related applications to provide a deeper insight on the phenomena which are relevant in nature and industry, e.g., flow in porous media, multiphase and multicomponent flow, interfacial phenomena, microfluidic systems, complex fluids and materials processing, hydrodynamic instabilities and flow control, atmospheric and oceanic fluid dynamics, granular flows and gravity currents. We have a wide expertise in heat and mass transfer in multiphase flows, turbulent flows, microflows and biological flows, optical techniques.

Research Areas

- Computational fluid dynamics and heat transfer

- Experimental fluid dynamics and heat transfer

- Flow boiling in microchannels

- Dropwise Condensation on textured surfaces

- Optical techniques

- Microfluidics and heat transfer

- Targeted drug delivery using magnetofluidics

- Hydrodynamic instabilities

- Vortex dynamics

- Dielectric Barrier Discharge plasma actuator for jet vectoring

- Droplet hydrodynamics of protein crystallization

- Heat transfer in nanofluids

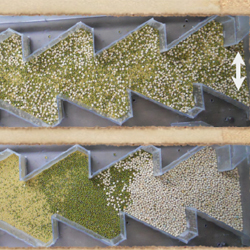

- Design of grain separators for agri/pharma sectors. Development of relevant computational tools

- Heat Transfer in Rotary Kilns used for Drying and Production of Cement

Chaos in Stratospheric polar Vortex

Research Laboratories:

- Fluid mechanics Laboratory

- Computational Fluid Dynamics Laboratory

- Computational Heat Transfer Laboratory

- Micro-scale Transport Laboratory

- Phase-change Thermal Systems Laboratory

- Water Tunnel Facility

Pulsating Heat Pipes

Associated Faculty

Gautam Biswas, Ph.D. (IIT Kharagpur) (on deputation as the Director of IIT Guwahati): Computational fluid mechanics and heat transfer, turbulence

P. S. Ghoshdastidar, PhD (South Carolina) : computational heat transfer, rotary kiln modelling, non-Newtonian flow and heat transfer, simulation of boiling heat transfer

Anirban Guha, PhD (University of British Columbia, Vancouver): hydrodynamic instabilities, wave mechanics, vortex dynamics, chaotic flows, transport and mixing, gravity currents, flow over topography

Sameer Khandekar, PhD (Uni-Stuttgart): thermal management, passive heat transfer, heat pipes, energy systems

K. Muralidhar, PhD (Delaware): optical techniques, flow control hierarchical porous media

P. K. Panigrahi, PhD (LSU): laser based instrumentation, flow control, CAD of thermal systems, turbulence, micro-fluidics and heat transfer

Arun K. Saha, PhD (IIT Kanpur): turbulance, chaos & bifurcation, vortex dynamics, hotwire anemometry, gas hydrates, experimental fluid dynamics and heat transfer, computational fluid dynamics and heat transfer

Subrata Sarkar, PhD (IIT Madras): turbomachinery, turbulence, computational fluid dynamics, LES, experimental fluid mechanics, heat transfer

Ishan Sharma, PhD (Cornell University): mechanics of granular media, modeling granular systems for geophysical and industrial applications. stability and vibrations of structural and fluid-structural systems

Highlights

- List of candidates from CFTI selected for provisional admission for PhD program in Mechanical Engineering for the session 2025-26-I.New

- Department of Mechanical Engineering, IIT Kanpur Presents 2nd Mechanical Sciences Young Investigators Meet MSYIM 2025 17-19 March 2025. Visit the website for more details: MSYIM 2025

- Guidelines for the Application of Institute Post Doctoral Fellows

- Applications invited for direct PhD students for the semester 2025-26-I. Last date of application February 20, 2025

- List of Selected candidates: Winter PG Admission 2024

- Candidates Shortlisted for Interview: Winter Admission PhD Programme 2024

- Dates for PhD winter admission 2024 written exam and interviews: November 27-28, 2024

- Reporting date of all new PG students: Jul 18 - 19, 2024

- Departmental Orientation of new PG Students: Jul 20, 2024, 2:30 PM onward, Venue: L16

- PhD admission (Round 2): Application form available here. Last date of application: 4th July 2024. Online written test: 7th July, 2024, Online/Offline Interviews: 10th July, 2024

- M.Tech. Admission (through COAP): Cutoff score, Vacancy and fee paid data

- Selected candidates for provisional admission in PhD programme

- Selected and WL candidates for MS(R) admission (Institute-sponsored category) Round 1

- Rolling advertisement for faculty recruitment